Doh! Yours came in while I was answering the last. Great post, thanks for the pointers. A few quick answers:

Yes, that's exactly what this is! I chose tubing size, tangs, and cylinder all based on what I had in my inventory. If buying I might have gone with 1-1/2 x 3 inch tubing, rather than 1-1/2" square. But I can always add a 1/4" x 1" or 2" spine atop the arm to add strength in the vertical direction, if needed. If I decide to cut a curve in some 6" x 3/8" flat stock, I could actually put a curved spine (tooth) on the bottom of the thumb.

Two options:

First, I could quickly and easily add another tube section mitered onto the end:

View attachment 777104

(click for full size)

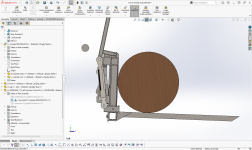

Second option is more work without a plasma cutter, but I could cut a piece of 6 x 3/8" flat stock I have into a curve, and weld it onto the bottom of the arm. This might be prone to side-bending if it's just a single thickness with much extension from the arm:

View attachment 777105

I thought I'd be able to more slowly release it with the straight arm than the curved, to be honest. Have to think that thru, as one serious shortcoming is the fact that the 3rd function I have available to control this is off a "bang-bang" electric solenoid controlled by thumb switch on my joystick, it's not proportional.

Speaking of which I was planning to add needle valves or restrictor plates to the input ports on the cylinders to be able to adjust thumb speed, unless Deere offers some valve similar to the 3-point float-down valve, to do the same right on the tractor.

The most frequent use will be lifting logs off a pile and setting them on the ground for bucking, in which case I think I can control the descent by how steeply I angle the forks down. The other potential use would be lifting logs out of a trailer, but I'd need shorter forks to get into the trailer more easily, and I'd have to be careful not to catch the far wall of the trailer with the thumb. It's a closed-side trailer with a railing about 2 feet above the floor:

View attachment 777108

Thanks! Yes, spent my career as a design engineer, and I'm all too familiar with those caught in analysis paralysis. Get it close, then build it. You'll learn more from rev.A than you think, and quickly mod it or spin rev.B to be much better.