You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Simple Grapple Design done!

- Thread starter polemidis

- Start date

- Views: 7901

More options

Who Replied?

/ Simple Grapple Design done!

#21

Ok hear you!The first thing a non-greaseable pin will do is rust, jam, or gall in the hole preventing disassembly without large amounts of jacks, chains, big hammers, torches, mashed thumbs and swearing. Ask me how I know. Do not rely on any lubrication method that requires disassembly of parts to add lubrication. If anything, lube parts while in place to aid in disassembly when needed.

I don't know the metric numbers off the top of my head, but for 1/4-28 zerks, you drill in from the end 7/32, then tap 1/4-28 (fine thread). Drill crosswise through the diameter to intersect inside the mechanism, can be any size from 1/8 to 1/4". Be careful of the bit catching and breaking when it intersects the other hole. If the pin is mild steel, it is very easy to do.

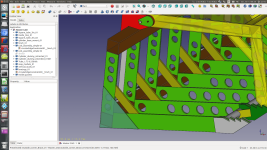

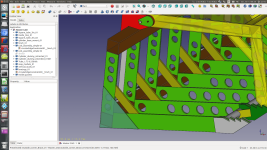

I designed this grapple for a)pick up limbs and brush as I am logging, b) stack green hardwood logs to a pile, c) load the firewood to the trailer. (will be possible if I add extra bolt-on narrow tines), d) maybe some rocks in that descending order. I never thought to use it as a root grapple but you are right for such a use a lot more support would be needed. Even though I am sceptical if that design will be able to stand up to that abuse. For a root grapple I believe the tines should not extend that much, and should be one piece with the vertical members.I'm not an expert and don't have a grapple as my caveat, but you may want to add some more flat bar for support and strength in key areas.

So I finished the BOM you can see them here

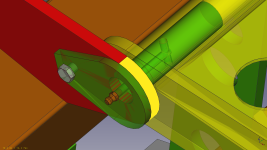

Whoever wants the 3dmodel can download it from here

BUT..... the grapple will weight 448lbs without the cylinders. Isn't that tooooo heavy, that will restrict me from lifting 16ft green oak logs? max diameter around 16in. My tractor has lifting capacity 1800lbs at the pivot

I am so close to start fabricating and I have all kinds of second thoughts, like

a) The square tubing (the 2 brown ones) are 3" x 1/8" . Isn't too thin?

b) Mostly everything is designed out of 3/8" , should I downgrade to 5/16"? it will save my around 50lbs

c) If not what about downgrade to 5/16" and choose higher grade steel?

d) Or maybe 63" its just to wide of a grapple for me?

e) Anywhere else I could save weight? MAybe do just the lids from thinner material? But that will just make the steel order more complicated and I will have lots of leftovers.

Whoever wants the 3dmodel can download it from here

BUT..... the grapple will weight 448lbs without the cylinders. Isn't that tooooo heavy, that will restrict me from lifting 16ft green oak logs? max diameter around 16in. My tractor has lifting capacity 1800lbs at the pivot

I am so close to start fabricating and I have all kinds of second thoughts, like

a) The square tubing (the 2 brown ones) are 3" x 1/8" . Isn't too thin?

b) Mostly everything is designed out of 3/8" , should I downgrade to 5/16"? it will save my around 50lbs

c) If not what about downgrade to 5/16" and choose higher grade steel?

d) Or maybe 63" its just to wide of a grapple for me?

e) Anywhere else I could save weight? MAybe do just the lids from thinner material? But that will just make the steel order more complicated and I will have lots of leftovers.

This is why a lot of people simply buy one...someone else has already made about six of these and learned all the lessons. Like using a higher strength steel which is more expensive, so that the end product can be lighter. When we start out thinking "it is just steel, how hard can it be...?" we very often do not see the decades of learning that went into getting something into its final form.

The smaller the machine, the more the weight counts. Believe it or not, 70 lbs made a big difference on one of my machines.

To me, the most surprising thing is how the commercial guys like EA can make these for what they sell them for and still have enough cash flow at the end of the day to keep the lights on and the staff in cheese whiz and coffee.

The smaller the machine, the more the weight counts. Believe it or not, 70 lbs made a big difference on one of my machines.

To me, the most surprising thing is how the commercial guys like EA can make these for what they sell them for and still have enough cash flow at the end of the day to keep the lights on and the staff in cheese whiz and coffee.

They sell them about $2000. Hydraulics cost $200, the higher grade steel about $500?? The freight $150, I think there is enough margin to cover the labor costs, the laser cost and make a normal profit especiallly when they get over the prototyping stage.

But the impressive thing is that today -in contrast with a few years ago-, we have professional and free CAD programs to design it. And also run the Finite Element Analysis. It is that I -yet- do not trust myself. My experience with steel is zero, I have welded less than 2-3 hours total in my life, and i first used a tractor 4 months ago!

And here is the magic of the open source. I have spent about 200hours CADing, and you guys have spent 4hours helping me. I have the design open to anyone. When I build mine, whatever feedback with be posted on my webpage. The next guy who will build it will have all that for free. And every "next" guy will have a larget pool of feedback. Can we design all the major implements that way?? I think we can. I am developing the firewood processor, the cost will be about $6000 compared to $26000 of the commercial product, and a well rig for shallow (60-80ft) wells. I believe that the FreeCAD, and Open Source in general will have a huge impact on the hardware we are using.

But the impressive thing is that today -in contrast with a few years ago-, we have professional and free CAD programs to design it. And also run the Finite Element Analysis. It is that I -yet- do not trust myself. My experience with steel is zero, I have welded less than 2-3 hours total in my life, and i first used a tractor 4 months ago!

And here is the magic of the open source. I have spent about 200hours CADing, and you guys have spent 4hours helping me. I have the design open to anyone. When I build mine, whatever feedback with be posted on my webpage. The next guy who will build it will have all that for free. And every "next" guy will have a larget pool of feedback. Can we design all the major implements that way?? I think we can. I am developing the firewood processor, the cost will be about $6000 compared to $26000 of the commercial product, and a well rig for shallow (60-80ft) wells. I believe that the FreeCAD, and Open Source in general will have a huge impact on the hardware we are using.

Will the OP please check the link to the 3D cad? I get an error, but maybe it's just me. I was able to see the BOM. Thanks

I just downloaded it and opened it just to check it. It looks fine. What exactly is the problem? You can use Freecad v0.16 to open it, but it is made with Freecad v0.17 so ideally use that daily version. If you use solidworkds or some other CAD let me know so I can export it to .step format. And if you want to edit it the individual parts I will upload later these too. I will put some instructions on my wiki page.

ktm250rider

Silver Member

- Joined

- Oct 7, 2004

- Messages

- 236

Woild love to see the firewood processor. Keep toying with the idea of building one with my current timberwolf.

rScotty

Super Member

- Joined

- Apr 21, 2001

- Messages

- 9,843

- Location

- Rural mountains - Colorado

- Tractor

- Kubota M59, JD530, JD310SG. Restoring Yanmar YM165D

SNIP....

But the impressive thing is that today -in contrast with a few years ago-, we have professional and free CAD programs to design it. And also run the Finite Element Analysis. It is that I -yet- do not trust myself. My experience with steel is zero, I have welded less than 2-3 hours total in my life, and i first used a tractor 4 months ago!

And here is the magic of the open source. I have spent about 200hours CADing, and you guys have spent 4hours helping me. I have the design open to anyone. When I build mine, whatever feedback with be posted on my webpage. The next guy who will build it will have all that for free. And every "next" guy will have a larget pool of feedback. Can we design all the major implements that way?? I think we can.

I think we can design things that way. It is fun to do, but still requires that there be people who will actually build and use them so that everyone learns from the mistakes.

For instance, I think that the "heel" of the lower part of the design is too thin. There is 1/8" steel being used at a sharp corner right where it is bound to get a lot of wear. While doing back-dragging for example. That is something that FE Analysis cannot predict. Most solid buckets solve that problem by making the back of the bucket curved. But bending heavy steel into a radius is just not appropriate for a home-built design.

And maybe I am wrong to be concerned about that steel being too thin. All I have is an opinion.

So the question is this: Do we try to design everything so that it won't ever wear or break and suffer needless expense and weight? Or do we deliberately make it as simple and light as possible and allow the design to evolve as needed?

rScotty

Working file now. Thanks!I just downloaded it and opened it just to check it. It looks fine. What exactly is the problem? You can use Freecad v0.16 to open it, but it is made with Freecad v0.17 so ideally use that daily version. If you use solidworkds or some other CAD let me know so I can export it to .step format. And if you want to edit it the individual parts I will upload later these too. I will put some instructions on my wiki page.

Woild love to see the firewood processor. Keep toying with the idea of building one with my current timberwolf.

Its here. But I paused developing it for now as the plow and the grapple are a priority. I will start working on that right after. (in a 2-3 weeks)

rScotty I also think that welding the 3/8" tines(or 5/16") to the 1/8" square tube will not give the better results. I will upgrade it to 1/4". Opinions is what I am looking for anyway! If I wanted sure solution I would go to an engineer!

As for me so far I only design what I need. And thats the grapple, the snow plow, the well rig, the firewood processor, maybe a backhoe and then the CEB press (compressed plinths out of dirt, the machine is already made in Opensourceecology.org, i just have to upgrade it). As soon as it makes economical sense. For example I will now waste my time into a tiller or bush hog. There are so many used ones out there.

The other difficult part is how to get organized. In order a design to be fun, a collaboration of some people is needed. Look at my firewood processor above. Its a hugee project. After a while it get boring. And it could be easily split. The splitter, the conveyor, the chainsaw and the feeding system. And someone else can do the hydrauylic components which for me is a pain! I will do it, but its drains my energy.

Here are some similar links:

- Replies

- 52

- Views

- 12K