polemidis

Gold Member

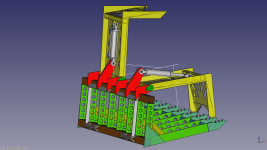

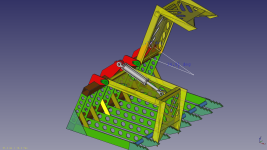

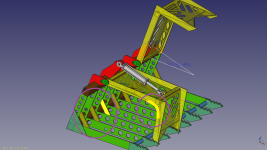

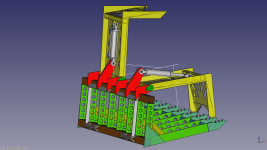

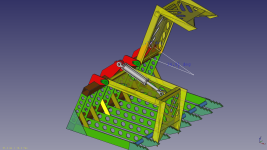

Hello to the community. Finally I finished the design of my grapple. I made quite a few changes from my previous post -if you remember it-. I change the approach because right now its not easy for me to handle a full 3/8" sheet, and I do not want to give the cutting to someone else because of the cost. Its redesigned in a way that most of us can built it out of flat bar. A plasma cutter will definitely help for the hinges ,the multiple mounts, and the holes to the tines. The latter reduce the weight by around 30lbs, and when I run the FEM analysis it didn't show any significant difference between the whole tines and the tines with the holes.

The tines are 3/8", and the plates on the lids are gauge 10 (I feel its too thick??). Solid steel for pins. Without the 2.5" x 6" cylinders and the welds the total weight is 298lbs.

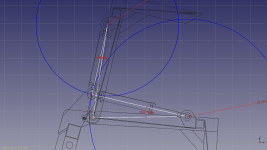

Clamping force at the closing position, starting with 2250psi is 2230lbs (2250*3.14*2.5^2/4*sin(14.91)*22/28)

Can you plz critisize it? Any comments, ideas, suggestions etc are welcome. Anything else that I may consider before I order the steel and start the fabrication process. I mostly need the negative ones, not trying to feed my ego today, rather than avoid mistakes :drink:

I know there is a lot of welding, but thats ok, I am just starting to weld I need practice.

Here is the current CAD feel free to download it and use it for any reason you feel like. Next week I will have the complete BOM at the same link.

The tines are 3/8", and the plates on the lids are gauge 10 (I feel its too thick??). Solid steel for pins. Without the 2.5" x 6" cylinders and the welds the total weight is 298lbs.

Clamping force at the closing position, starting with 2250psi is 2230lbs (2250*3.14*2.5^2/4*sin(14.91)*22/28)

Can you plz critisize it? Any comments, ideas, suggestions etc are welcome. Anything else that I may consider before I order the steel and start the fabrication process. I mostly need the negative ones, not trying to feed my ego today, rather than avoid mistakes :drink:

I know there is a lot of welding, but thats ok, I am just starting to weld I need practice.

Here is the current CAD feel free to download it and use it for any reason you feel like. Next week I will have the complete BOM at the same link.