Hand sharpening drill bits is a great skill to have, but comes second to learning how to drill metal. If you don't burn up your bits to begin with, then there's a lot less sharpening (or throwing out and re-purchasing) to be done. Learning how to drill metal by hand, like hand sharpening, is an acquired skill. Most everyone doesn't do it properly, doesn't care that there's a proper way to do, and blames all their problems on "crappy bits."

I work with maintenance guys and I cringe every time I see one of them with their drill in 3rd gear, 1/2" bit screaming and squalling, belching smoke from the tip... which means I spend a lot of time cringing. I've tried to explain it to them before, demonstrate the proper technique, but they don't care. Why would they, when they have a magical self-replenishing drill bit drawer?

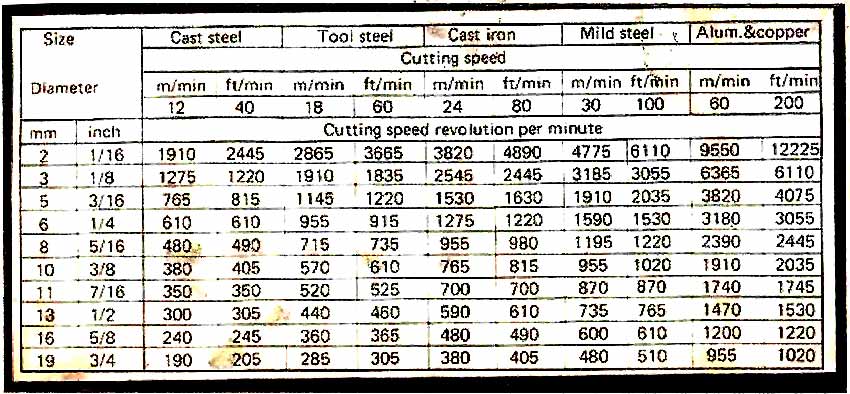

Different kinds of metals like to be cut at different speeds and different feed rates. All of them (except maybe cast iron and bearing bronze) like to be lubricated during cutting regardless of speeds and feeds (and some prefer specific lubricants, ex: aluminum = WD40). Speeds and feeds for various metals are typically given in "surface feet per minute." You take this number from the table (google "speeds and feeds for _______", fill in the blank for whatever metal you're drilling) and find out the RPM you need for the diameter of drill you're using, and the feed rate, and so forth. here's an example that gives you actual RPM so you don't have to the math:

Say you're using a 3/8" bit in mild steel, you want to be running around 1000RPM.

This chart doesn't give you the feed rate or lubricant type, but you can find that on other charts.

If you're going to be drilling a lot of the same size hole, the best thing you can do in my opinion, is do your homework and your math for that one bit size in that material, and do a few good holes per the numbers on a drill press, take a mental video of what that looks like when done at the proper feed & speed. Then go do it by hand.

Do this each time you drill a different sized hole or in a different material, and build your mental video library. Your mind is a powerful tool, you don't need to do this for each and every size of bit; a big one, a small one, a few in the middle; It only takes a few examples and your mind will fill in the blanks.

Once you know what a properly drilled hole looks like as it's happening, you'll be able to make it happen in almost all circumstances going forward. Your bits will last, and when they don't you'll be able to say with authority that they actually

are crap.

I stick to generic 135 degree HSS bits. Plain jane, no fancy metallurgy, no fancy coatings, no fancy tip geometry. They work in 99% of applications. Last set I bought was DeWalt and they work just fine. I will use split points on occasion if I'm too lazy to center punch a bunch of holes.

When drilling anything over 1/4" I'll work my way up to final diameter in a few steps, because drilling a 3/4" hole in steel with no pilot sucks.

In summary, learn how to drill before you go investing in expensive bits that you're bound to burn up only slighly slower than the cheap ones you're burning up now. Then learn how to sharpen that pile of burned bits. Odds are, there's not a single thing you need to purchase, and not a single thing that you

could purchase, to get past this issue. Skill building is required.