Southernspeed

Gold Member

I’m sure this story sounds familiar. I badly needed to rebuild the steering gearbox, then when I’d got that removed I thought I may as well split the tractor and do the clutch that will need replacing in the near future…. and then there’s that noisy transmission bearing ….

So steering g/box is on the bench, rebuilt.

Trans is stripped awaiting parts.

Clutch stripped awaiting parts.

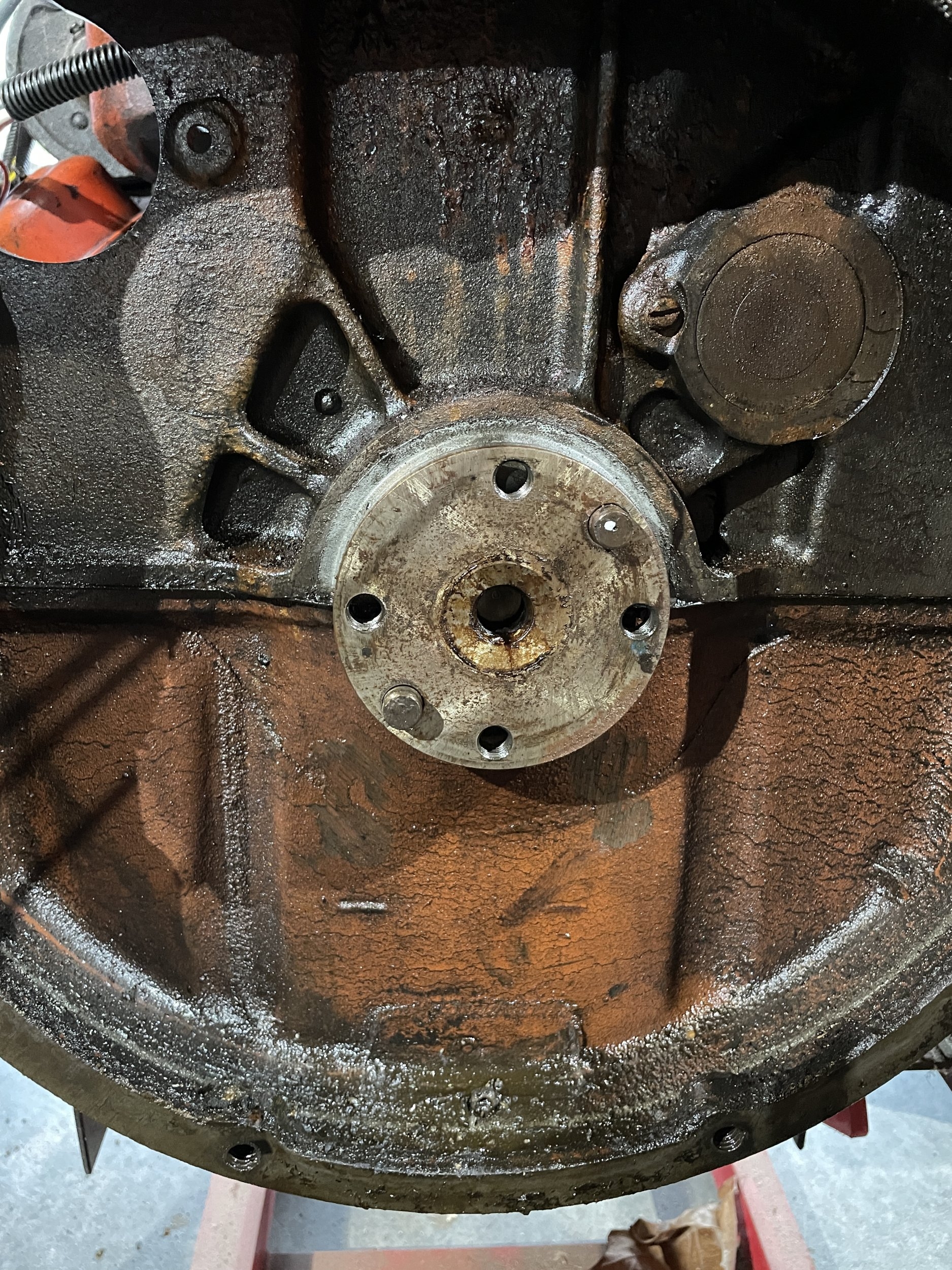

But now the flywheel is off I’m looking at a very oily housing. One possibility is that the steering g/box had NO oil in it, just remnants of grease around the gears. Someone had replaced the roller bearings with those nylon bushes but they had worn badly. Freeze plug just about fell out so IF they’d put oil in there, that could’ve leaked through.

But how susceptible are 8Ns to oil leaks from the engine? ( rear main seal or camshaft plug) I really don’t want to be doing a full engine strip right now. I also don’t want to mothball it, in pieces, until winter

So steering g/box is on the bench, rebuilt.

Trans is stripped awaiting parts.

Clutch stripped awaiting parts.

But now the flywheel is off I’m looking at a very oily housing. One possibility is that the steering g/box had NO oil in it, just remnants of grease around the gears. Someone had replaced the roller bearings with those nylon bushes but they had worn badly. Freeze plug just about fell out so IF they’d put oil in there, that could’ve leaked through.

But how susceptible are 8Ns to oil leaks from the engine? ( rear main seal or camshaft plug) I really don’t want to be doing a full engine strip right now. I also don’t want to mothball it, in pieces, until winter