rcrcomputing

Platinum Member

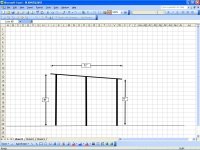

Give you an example. You would not want to use a double 2x12 with plywood in between them for a 16' garage header because of the possibility of sagging..

Soo, in the application, I would notch the posts as instructed and use a double 2x12 with plywood between them.

Soo, in the application, I would notch the posts as instructed and use a double 2x12 with plywood between them.