4570Man

Super Star Member

- Joined

- Apr 7, 2015

- Messages

- 19,005

- Location

- Crossville, TN

- Tractor

- Kubota M59, Kubota L3800, Grasshopper 428D, Topkick dump truck, 3500 dump truck, 10 ton trailer, more lighter trailers.

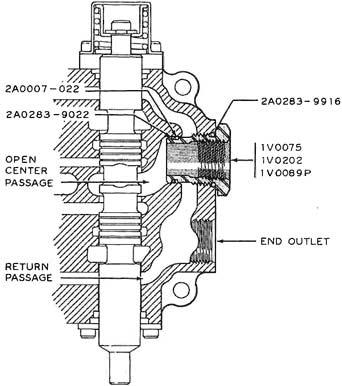

I changed the valve on my splitter to a double way detent valve. I think you could add some linkage to reverse the valve at the end of the stroke and you wouldn’t have any electronics.