It is a mystery to me how and why Kubota made those wires to the panel switches so short. My first guess is they used some sort of micro-robotics. Or maybe they suspended the panel in mid-air, and then assembled the entire rest of the tractor around and under it.

What I did was to extend all the wires by six inches, tuck them neatly away where they are protected and can't get into trouble.

$200 for a Kubota 3rd function switch?? That is just a standard switch. Kubota doesn't make them, they buy them. Amazon sells them for ten bucks. In fact, the ones on Amazon are the same industrial switch designation, but a much higher quality. I replaced that front push button on/off switch with a much nicer one from Amazon for ten bucks.

Amazon claims to have 80 pages of this type of switches....If I ever need evidence that the manufacturing world has gone mad, I will point to 80 pages of different companies making essentially the same switch for about the same price.

The retail switch prices range from a couple of bucks (without LED) to $15 with choice of LED colors.

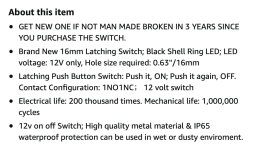

I actually bought several and threw the unused ones in the electrical drawer to see if they would reproduce. Near as I can tell, all the switches are the same high quality & they all work the same. Some have sockets, some have colored wires, others are push-on connectors. Key words are: 12V, 10 amp, on/off latching, 16mm (5/8"). and the designation "1NO1NC" or something close to that.

ABOUT THAT LOADER CONTROL: The

M59 FEL joystick can get sticky. Pull back the boot, and beneath the

M59 loader control joystick is a fantasically over-complicated series of little levers and adjustments that pull cables in sheaths going down to the actual loader control valve which is positioned in the much harsher wet and muddy environment beneath the deck. The relay-actuated FEL aux hydraulic valve is down there in the mud too. If you figure out how to lubricate those joints and cables, all the controls sure works better.

Enjoy,

rScotty

View attachment 850460View attachment 850461View attachment 850462View attachment 850463