Eyecatcher

Gold Member

- Joined

- Apr 12, 2012

- Messages

- 367

- Location

- Pomona Park Florida

- Tractor

- Yanmar EX450, Ford 8N/2N, Case 580C backhoe, Massey 185

My grandaughter has come to stay with us and wants to have a garden. It's just about time to plant tomatoes her in N. Florida, so we're gonna give it a go.

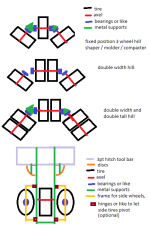

I just replaced all the discs on my old disc harrow, and have a bunch of 16" discs w/1 1/8" sqh I took off. Need to come up with a hub and axle for them to fit on. All of the ones I see for sale commercially have 4 bolts through the disc. Is it possible to drill thru them to mount this type of hub, or are they too hard?

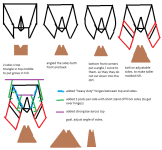

I've got a couple of quills (I think thats what they're called) off an old John Deere mower deck that are in pretty good shape, Maybe I can modify them. I have a 3 point attachment with two arms that was made to tote citrus boxes. I cut the arms shorter, and mounted the rippers off my box blade to use for a sort of root rake. Haven't tried that yet, but I have room to weld a 2"square tool carrier behind that, would work well to mount the discs. Tractor is at the dealers, but as soon as I get it back, I'll post some pix. I'm open to all suggestions. I also have some 1/14 round bar for shanks if I can figure out how to attach them to the quills.

I just replaced all the discs on my old disc harrow, and have a bunch of 16" discs w/1 1/8" sqh I took off. Need to come up with a hub and axle for them to fit on. All of the ones I see for sale commercially have 4 bolts through the disc. Is it possible to drill thru them to mount this type of hub, or are they too hard?

I've got a couple of quills (I think thats what they're called) off an old John Deere mower deck that are in pretty good shape, Maybe I can modify them. I have a 3 point attachment with two arms that was made to tote citrus boxes. I cut the arms shorter, and mounted the rippers off my box blade to use for a sort of root rake. Haven't tried that yet, but I have room to weld a 2"square tool carrier behind that, would work well to mount the discs. Tractor is at the dealers, but as soon as I get it back, I'll post some pix. I'm open to all suggestions. I also have some 1/14 round bar for shanks if I can figure out how to attach them to the quills.