General Lee

Veteran Member

I am in the process of erecting a fence. First time for me. I'm going with post and plank design w/ 2x4 welded wire to keep the chickens and ducks in. I'm in the beginning stages but the problem I'm running into the post post height varies a little. The welded fence that will be attached is 60'' tall.

Any tips or tricks so that my welded wire fence won't be higher then posts in some areas as I go along? I don't mind trimming the top of a post if I need to, its when they are to short by an inch or two. The posts are round treated posts 6 1/2 foot long from TSC.

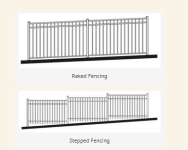

Edit to add - Also my area is not flat. Slopes, uneven terrain. When I attach the planks I should try and follow the contour of the land correct? Meaning if the area slopes my bottom plank should follow the slope to be more appealing to eye, instead making it level ?? I see it having 8'' on one end and if made level ..16'' on the other end. Sorry for the ignorance, like I said, first time doing this.

Any tips or tricks so that my welded wire fence won't be higher then posts in some areas as I go along? I don't mind trimming the top of a post if I need to, its when they are to short by an inch or two. The posts are round treated posts 6 1/2 foot long from TSC.

Edit to add - Also my area is not flat. Slopes, uneven terrain. When I attach the planks I should try and follow the contour of the land correct? Meaning if the area slopes my bottom plank should follow the slope to be more appealing to eye, instead making it level ?? I see it having 8'' on one end and if made level ..16'' on the other end. Sorry for the ignorance, like I said, first time doing this.

Last edited: