Shield Arc

Super Member

I love this phosphoric acid! It give results very fast.

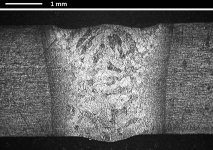

This is really dis hearting:shocked:. This is the 3/8-inch thick V-butt test plate I ran with the Everlast 120-volt Mig welder. Wire speed maxed out, and the voltage turned down just a bit. This is the last 1/2-inch of the plate. So it should have been about as hot as it was going to get. And I preheated this test plate before I started welding.

This is really dis hearting:shocked:. This is the 3/8-inch thick V-butt test plate I ran with the Everlast 120-volt Mig welder. Wire speed maxed out, and the voltage turned down just a bit. This is the last 1/2-inch of the plate. So it should have been about as hot as it was going to get. And I preheated this test plate before I started welding.