k0ua

Epic Contributor

I think your filed welds on the nuts are beautiful and give it a special custom look.

Very nice design, execution and expense to solve a problem that doesn't exist.

My LA524 has a level bracket on top of the bucket, well visible from the operator station. I never have an issue with leveling the bucket, observing the bracket and adjusting, by feel. So many tractor skills, well executed, require experience which results in feel for the machine. For instance grading a road with a back blade after having dropped spoil which contains roots and grass tops, dragging the load down the road and feathering the blade so as to leave the dirt behind while collecting the plant material so it can be collected with a level bucket at the end of the run and deposited off the road. The blade becomes an extension of the operator and no LED lights are going to beat the native relationship between the blade position and the operator's mind and hand on the control lever.

I too appreciate the quality of your modification but I chalk it up to your desire to pimp your tractor, which is just fine. I'll stick with the basics and develop my machine handling skills to achieve the desired results.

Respectfully submitted by a Machine Operator

Would you put the plumbing in series or in parallel to your normal loader valve?

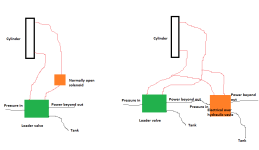

If you put it in series, you would need to manually curl the bucket & your simple on/off valve between the loader valve & cylinder would trip according to the sensor. Then the system would immediately go into relief, pretty much like you limited out the cylinders. Once you heard the relief valve start squealing, that would just be a signal to let off the curl lever. I'm sure you could replace the loader valve with something detented to pop out, but that would be a bit costly & complex (and beyond my knowledge for now).

If you plumbed in an open center electronically actuated valve into the power beyond loop you could probably have both your normal loader valve & your electronic return to level valve feeding the curl cylinders. When both valves are centered, it will block the work ports & not let the cylinder move. If you were to use either valve, it would open 1 work port to pump & the other to tank, just as normal. Essentially you'd end up with a normal loader valve operating as usual & an electronic valve initiated by a button or 2 to electronically return the bucket to level. Plumbing something in parallel like that would be more brainless to use I think, but harder & more expensive to implement.

Just brainstorming ideas based on my limited knowledge of hydraulics.

Thanks for commenting and helping out Fallon

I would like to put the valve between one of the two fel curl hoses at the quick connect. Just one quick connection. In and out of the solenoid /valve. I realize it will only stop one way.

Install an on/off button on the joystick and pilot light on the dash showing when power is on for the solenoid.

So after dumping the bucket, press the button on the joystick, power light on dash lights up to let you know the solenoid is waiting for the trigger. Once the bucket curls back up after dumping and hits my level sensor for my Fel level light (already on the tractor) . The solenoid kicks off the hydraulics to the curl and the bucket stops at level . Let go of the joystick, hit the on/off button off, go get another load.

(Nothing myself or any other operator can't do manually)

Could it be something that simple? Just seeing if I can make a simple auto level option.

Then the title of the thread would be

Electronic Fel level indicator with Auto level stop.:thumbsup:

Please I don't want to hear a good operator doesn't need this. I think we all know that.

Remember, I'm the guy who put central vacuum in my cab.

Anymore ideas? Will it work?

Very nice design, execution and expense to solve a problem that doesn't exist.

My LA524 has a level bracket on top of the bucket, well visible from the operator station. I never have an issue with leveling the bucket, observing the bracket and adjusting, by feel. So many tractor skills, well executed, require experience which results in feel for the machine. For instance grading a road with a back blade after having dropped spoil which contains roots and grass tops, dragging the load down the road and feathering the blade so as to leave the dirt behind while collecting the plant material so it can be collected with a level bucket at the end of the run and deposited off the road. The blade becomes an extension of the operator and no LED lights are going to beat the native relationship between the blade position and the operator's mind and hand on the control lever.

I too appreciate the quality of your modification but I chalk it up to your desire to pimp your tractor, which is just fine. I'll stick with the basics and develop my machine handling skills to achieve the desired results.

Respectfully submitted by a Machine Operator

Does anyone know if this will work? For a level stop.

If I put a 12 volt hydraulic flow solenoid between the curl fel connection hose of the tractor and

loader, once my "level" rod switch is activated and shuts off the hydraulic flow to the curl function,

will the bucket stop and be stiff at level until the solenoid opens again? Just like it is stiff when I

release the control lever? Or will there be play back and forth in the pistons?

Very nice work, WAX. It is nice to see such a practical device made and installed with such

good workmanship. I can esp see this helping on snowy nights, as you say. (I, too, have

pimped out my tractor with numerous mods.)

As for the hydraulic limiter you want to use: you can install a 12V spool-type solenoid

valve on one side (curl or dump) of your bkt cylinder circuit, and that would stop your

curl action when your switch hits the detent in your rod. I use one-sided solenoid valves

to do a similar function on my 4-in-1 bkt and hydraulic hoe thumb.

You can use a very small valve, however, like the HydroForce valves I used. Use a

normally-open valve, and avoid the more common poppet-type valves out there.

Go for it, and let's see what you come up with.

When I push into a load of brush with my loader like this I can't always see the attachment. I could, however, see the glow of lights through the brush. Or alternately, mount the lights closer to the operator station. Really cool would be an added inclinometer. I believe Waxman's solution to be for a problem that does exist.

is this the valve your talking about?

HYDRA FORCE 12 VDC N.O. SOLENOID VALVE

Very nice design, execution and expense to solve a problem that doesn't exist.

My LA524 has a level bracket on top of the bucket, well visible from the operator station. I never have an issue with leveling the bucket, observing the bracket and adjusting, by feel. So many tractor skills, well executed, require experience which results in feel for the machine. For instance grading a road with a back blade after having dropped spoil which contains roots and grass tops, dragging the load down the road and feathering the blade so as to leave the dirt behind while collecting the plant material so it can be collected with a level bucket at the end of the run and deposited off the road. The blade becomes an extension of the operator and no LED lights are going to beat the native relationship between the blade position and the operator's mind and hand on the control lever.

I too appreciate the quality of your modification but I chalk it up to your desire to pimp your tractor, which is just fine. I'll stick with the basics and develop my machine handling skills to achieve the desired results.

Respectfully submitted by a Machine Operator