captainblackmer

New member

Hello,

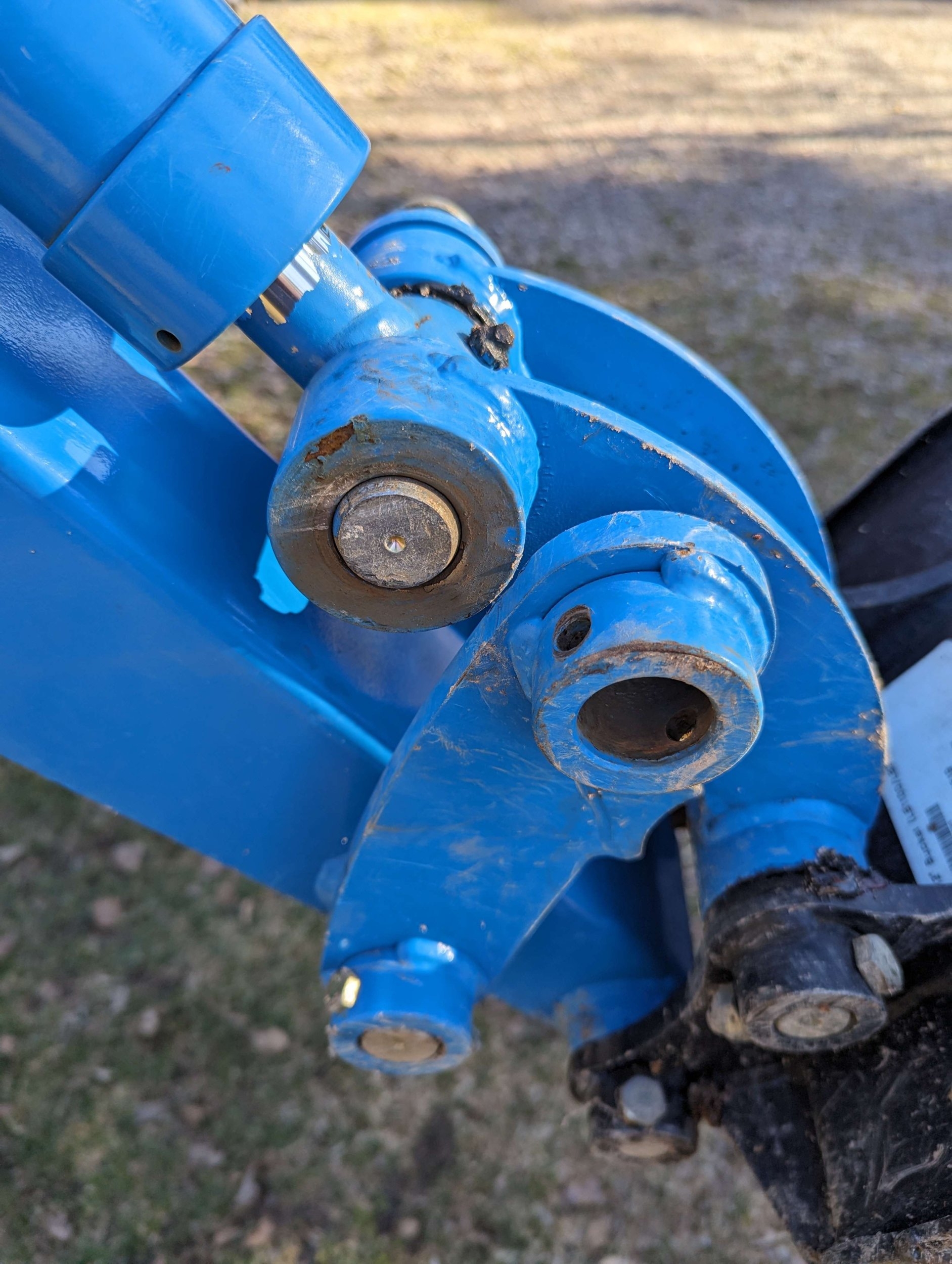

I was digging up a stump and just as I finished I noticed this backhoe pin hanging out half way. I tried putting downward pressure on the other side to line things up again but still couldn't get it line dup enough to go back in. I think the bracket on the side still pinned might be bent a little.

I'm no millwright but I do like learning new things. Anyone have any ideas on how I might get this lined up again and repinned? Thank you for any help!

I was digging up a stump and just as I finished I noticed this backhoe pin hanging out half way. I tried putting downward pressure on the other side to line things up again but still couldn't get it line dup enough to go back in. I think the bracket on the side still pinned might be bent a little.

I'm no millwright but I do like learning new things. Anyone have any ideas on how I might get this lined up again and repinned? Thank you for any help!