thank you all, appreciate the feedback. I haven't yet used the remotes on this tractor (its a 2005 with 1300hrs), is it as simple as plugging in the lines and away the splitter goes? Or do I have to engage the flow lever one way or another?

Yes, you will need to plug the hoses from the splitter into the tractor remote,

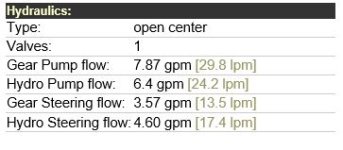

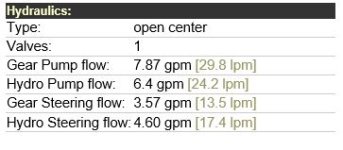

then if and it should be an open center valve on the splitter,

you will need to put your remote into a full flow mode,

if your valve has a detent which will hold the valve in position your all set,

if not you will need a bungee cord to hold the tractor valve in the on position.

Be aware that which port you connect to on your valve to the splitter can make a difference.

It sounds like you are not familiar with using remote hydraulics.

Many times on a piece of equipment which has it's own control valve it is desirable to only have one line connect to the remotes outlets.

Picking up pressure from the remote when activated and supplying that pressure to the implement valves input port.

With the return from the implement returning directly to the tank (reservoir) of the tractor.

With this type of arrangement it is not possible to reverse feed a remote valve which could possible damage it or cause some motors or operations to run backwards.

When you operate your tractors remote valve in one direction you apply pressure to one port connection and the other port opens for a return to tank,

when the tractors remote is operated in the other direction the port that was a return to tank is now the pressure port and the previous pressure port is now the return to tank.

In the center position neither port is open to return or supply.