I'd suggest you ask the garage door guy to frame the opening so he's happy with it. Or suggest someone that you can hire to frame it. No offense, but it doesn't sound like you're familiar with what's needed.

Beams are horizontal load-carrying structures. Yet you seem to be referring to vertical columns or studs, etc. as "beams". Maybe I'm reading this wrong. ???

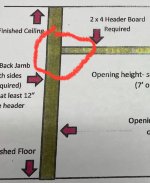

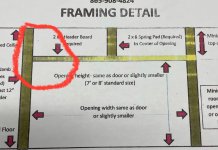

A "header" is a load-carrying structure that is supported on both ends by jack-studs or cripples or . . . various names . . . The HEADER carries the load and spans the opening that can't have studs directly below supporting the weight of the roof or wall.

Sounds like your metal building is already self-supporting so you don't need a "header" -- you only need wood framing around the opening so the door weather-seal can be attached and allow the door to close against it. It will need to support the track and the moving weight of the door. The door frame has to be attached to columns or solid structural components.

You need to frame up an opening that will be solid. It will need to be attached to something rigid. (Assume you're not just attaching to the exterior metal.) Over the opening, frame it up using at least a 2x10 overhead and place spacers and bracing above so it's rigid. The door will require a torsion spring bracket that is lag-bolted into the "header" -- this needs to be rock solid and a 2x4 isn't nearly adequate.

View attachment 1998854