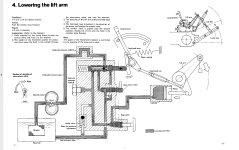

I believe that Vigo327 is saying that since the 3pt hitch is not going to be used at the same time as the backhoe is installed, then it is possible to use the 3pt hitch's internal circuit as a path for the backhoe fluid return flow. (backhoe fluid OUT).

He is drawing attention to the fact that there is a return path that already exists within the 3pt fluid circuit that has the right characteristics to be able to accept flow from the backhoe and directing it to the sump. It is the same bypass pathway that the tractor uses when the hydraulic pump is running but the 3pt is not in use.

Tractors all have some position on the 3pt control that selects that bypass path and directs incoming high pressure flow directly to the sump. On most tractors - not all, but most - this is the path selected by the 3pt control when the control is pushed all the way forward.

Some Kubotas even have a thumb screw designed to hold the control in the full forward bypass position.

He is also saying that if you plumb things that way, you do have to be careful to leave the 3pt control in the bypass position and not to actuate that 3pt control when the backhoe is connected.

I think that might work. It's worth a try. It has the advantage of simplicity.

If you are going to try it that way, I'm thinking the sketch needs to have some more detail so that everyone is on the same page. There are some high pressures in this solution, so be sure to use hydralic connectors, not standard plumbing connectors.

rScotty