This was published in American Iron Magazine in the August 2009 issue.

Please read and pass it on.

Brake Cleaner = Phosgene Gas

By Steve 'brewdude' Garn

Yep, I thought this time I was a goner! How simple it was to get in trouble. Please take the time to read this and pass it on. After time we see and read many warning labels that we no longer heed. We buy chemicals and sprays at a local parts house and think to ourselves how can this be so bad health wise if we use it, I am buying it over the counter? So, this is how my story starts.

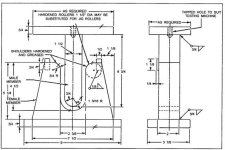

So I had a rush job welding 4 diesel semi tanks to patch that were pitted from road salt corrosion. Normally I spray a little carb cleaner, wipe it off, light the acetylene torch and preheat to get rid of any solvents. The gas station close to the shop was out of carb cleaner so I picked up a can of brake cleaner and went thru my regular routine. I even had the shop door open and the exhaust fan on. I started TIG welding (3pm Thursday) and had no problem in the beginning. Then, I started welding across a really pitted area and came across a couple of drops of cleaner still left in a deep pit. When I came close a small puff of white smoke puffed and immediately almost passed out. I then made it outside and sat for a while in the fresh air. After about 10 minutes I went to the office at the house and sat at the computer to check the warnings on the brake cleaner can when my whole left side started shaking for about 10-15 minutes. The can said ‘Vapors may decompose to harmful or fatal corrosive gases such as hydrogen chloride and possibly phosgene.

After reading about Hydrogen Chloride and then started researching phosgene. The chemical in the brake cleaner is Tetrachloroethylene. When this chemical is exposed with excessive heat and argon (used in MIG and TIG welding) it also produces phosgene.

Some Phosgene facts. Google Phosgene and read more!

It can be fatal with a dose as little as 4 parts per million.

Symptoms can be delayed from 6-48 hours after exposure.

There is NO antidote for Phosgene.

Long term effects can be chronic bronchitis and emphysema.

My breathing still was hard. So I called my wife in town (20 mins. away) and she said to call the ambulance which I didn't do. I waited at home for another hour and felt a little better so I decided to drive into town and meet my wife for supper and also living way out in the country brought me closer to the hospital in case I felt worse. The chlorine taste and smell in my nose and mouth was still very strong but went out later for pizza and then went to watch a basketball game. I felt a little better until I went outside after the game into the fresh air and then the smell and taste of chlorine almost overwhelmed me. I still went home hoping time would make me feel better.

About midnight (Thursday) I started coughing, my chest started hurting but thought that this would pass after a nights sleep. The next day (Friday)symptoms got worse and kidneys started hurting so I drank a bunch of liquids and cranberry juice. For 4 days pissed a lot of clear fluid with no smell. On Saturday I was really in a lot of pain. On Sunday I felt a little better and went to a friend’s house to watch the superbowl game. When I came home I felt very weak and tired. Monday I still was about the same. Tuesday I felt a little better and went into the shop for a couple of hours. Piss was very dark and a lot of smell this day. Still couldn't crap. Wednesday felt pretty good and I worked for about 5 hours. Thursday was even better day so I decided I would drive to Cincy with Chad to the VTwin expo on Friday. I felt okay but was very tired and weak. That Saturday I went out with friends but I didn’t feel quite right. I felt crappy on Sunday and left the expo about 2pm. The trip home was 375 miles and arrived home about 10pm that night feeling very tired. My wife made the comment that I looked awful (some home greeting). At midnight I lost all balance, was dazed, confused and could hardly talk so I then went to the Emergency room. My symptoms were Oxygen level low, sugar out of control, vertigo and I was hurting badly in my entire chest. They admitted me and put me in the ICU. They said my kidneys had probably shut down for those 4 days, my lungs were damaged so I had to be on oxygen and that I would have to be on insulin to keep my sugar in check. The doctor and neurologist called CDC to try to figure out what to do since there is no antidote for phosgene. Basically to try to rest and hope it gets better. After CT, MRI, EKGs, EEG and several other blood tests it looked like at this time there was no permanent damage. The EEG was taken because of the shaking earlier of my left side was a seizure caused by the chemicals. The EEG determined that there was no permanent damage. But the MRI showed fluid in sinuses and a build up of fluids near the brain. The gas scarred up my sinuses and then became infected causing these fluids. The 3 doctors I saw said I was really lucky to make it.

Now it has been 4 weeks. Another Doctor who specializes in toxology is now seeing me. He thinks I may have emphysema and chronic bronchitis. So at this time I am on nasal medicine and an inhaler. My sinuses are severely scarred and nose smell nerves are damaged. I still have that awful chlorine taste and smell. I am also going to ear, nose throat Dr on Thursday. I will also know later on any pancreas damage from the blood tests that I had taken. The insulin that I was taking had little effect on sugar and I can't keep it in control. So we are trying a different approach with Lantos (long lasting insulin) and other medicines. Sleeping is off and on and I will have a sleep test next Tuesday. I am feeling somewhat better but still very tired. This will go on for a while but I have full faith that all will be fine after time.

On some forums some suggest using a cleaner without this chemical. Other chemicals I found in other sprays in my shop include, xylene, toluene, methylene chloride, ketones, pentane, cyclohexanes, heptane, methyl ethyl ketone (MEK), methanol, tetrahydrofuran and petroleum napththa. There are actually more but you get my point, right? All the chemicals listed above have heath issues! So check your sprays and know the health hazards and their correct use.

Chris Maida has called and checked up on me several times. He said it is a shame I went thru this ordeal. But, I disagree. If it saves someone an illness or a death it is worth going thru this if this is what it takes.

Please read labels and warnings. Look up the chemicals you use. Also keep these sites and phone numbers nearby.

American Association of Poison Control Centers Phone # 1-800-222-1222

Centers for Disease Control and Prevention

Your local hospital phone #

Thanks to American Iron Magazine to publishing this!