LD1

Epic Contributor

Ld

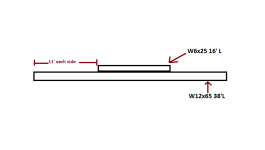

Is there an 18 deep beam in your table with similar flange to the small beam. If yes the two beams welded together would be a slightly stronger beam

I wish. The 6x12 has a 4" flange that is 0.280" thick. The lightest 18" beam 6" x 0.425" flange. And that light 18" beam has a smaller moment than teh w12x65 I would be starting with. So that dont work out.

There was this program called "beam boy" that would calculate all sorts of data related to beams and deflection and loading. I can't remember if you could give it custom shapes. You might try looking into that.

For Android smartphones there is an app called epic FEM, but doesn't allow custom shapes far as I know.

Beam boy dont allow custom shapes. (I use beam boy alot). Also tried a couple more beam tools I downloaded, but dont allow custom shapes.

I'm even drawing a blank on the moment calculations by breaking down into individual shapes.