LD1

Epic Contributor

Boy they sure dont make it easy.

I'll have to go through that and study everything tonight if I have some free time at work.

Without having the time to go through everything now, it appears the end result you gave solves for max deflection.

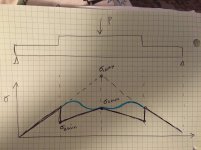

I dont think deflection is my concern. My limiting factor is bending stress in the beam. A taller beam with the same I4 sees more stress, but same deflection.

Keeping myself at 5:1 SF as far as stress is concerned, deflection is not a concern.

Does the same process apply for calculating stress of a double stacked beam?

We have solidworks at work. I am gonna see if there is anything in that program to play with as well

I'll have to go through that and study everything tonight if I have some free time at work.

Without having the time to go through everything now, it appears the end result you gave solves for max deflection.

I dont think deflection is my concern. My limiting factor is bending stress in the beam. A taller beam with the same I4 sees more stress, but same deflection.

Keeping myself at 5:1 SF as far as stress is concerned, deflection is not a concern.

Does the same process apply for calculating stress of a double stacked beam?

We have solidworks at work. I am gonna see if there is anything in that program to play with as well