roadhunter

Elite Member

Well done. I'm going to have to figure out a way to use my aux hydraulics to do similar. Very convenient to say the least.

Well done. I'm going to have to figure out a way to use my aux hydraulics to do similar. Very convenient to say the least.

My only problem with using hydraulics would be cost. Pulling some rough numbers out of the air...

Hydraulics:

$50-75 cylinder

$50-100 hoses

$100 control valve

$75 relief valve (so you don't break things at full machine pressure)

$10-20 brackets, bolts & stuff

Doing it electrically:

$60-100 linear actuator

$10-20 wire, switch & fuses

$10-20 brackets, bolts & stuff

My linear actuator might be marginal on power & it's longevity remains to be seen, but I'm hopefully. I still probably need to get a 6" actuator instead of a 4", but that was a measurement & parts sourcing flaw on my part, not a design flaw. Now that I've evaluated things on my mostly completed prototype I'm less concerned about the lack of an adjustable limit switch, which means more prospects for linear actuator options. A faster/stronger actuator might be a good idea if you can find one for cheap or afford a better one than I am using.

Interesting to see this come together. Well done - it is beyond my skill level so I'won't be powering my SSQA anytime soon but it has certainly given me ideas on how to use linear actuators (that may fit my skills).

I have to ask - what are you going to automate on the wife's chicken coop?

Interesting to see this come together. Well done - it is beyond my skill level so I'won't be powering my SSQA anytime soon but it has certainly given me ideas on how to use linear actuators (that may fit my skills).

I have to ask - what are you going to automate on the wife's chicken coop?

ovrszd, Many of these actuators have thermal protection. I'm sure most would agree that hydraulics are "best", it isn't as achievable. For me, if I had a 3rd function, it'd be for a grapple. So then I'd need an extra diverter for this so I could use the grapple too. This is easy, a switch and a couple wires. Its also very compact.

Cool. I'm with you on this project. I think it's very commendable that you've conquered it.

If you had 3rd function you could use a diverter valve and have both. That was my point earlier. Sorry if I sounded like I was bad mouthing your choice. I was not. Thanks again for posting this thread and including the detail you have.

Edit: sorry I reread and realized I wasn't talking to the OP. But my responses would be the same. Great thread that a lot of readers will learn from.

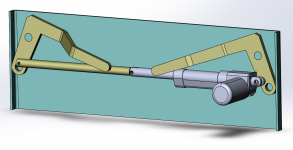

Super super crude (Dimensions aren't really right even), but this is my mockup....

Goals are to fully utilize the 6" of travel, using existing stops.

Make mounting easy.

Make mounting template, perhaps.

make parts list/instructions.

I've inquired with the linear actuator people, and for an extra $100 ($248 & 15 business days) they could make an actuator with the length required. That would make it bolt-in instead of having to make some sort of extension. I'm not sure that it makes sense yet, but its doable.

It would seem for $300-ish, this could be a professional-looking kit to be installed.

Food for thought......

<img src="http://www.tractorbynet.com/forums/attachment.php?attachmentid=418481"/>