pjb09

Bronze Member

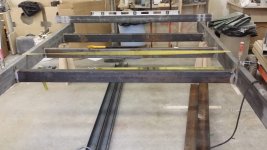

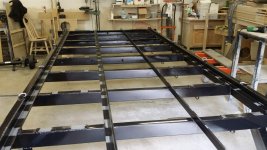

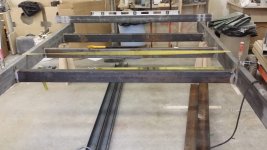

Decided I needed a trailer to move my BX25 from one property to another. Borrowing and renting proved to be a pain.

To move the tractor and a piece of equipment or two I figured a 16' car trailer would be about right. Searched the net and found a set of plans I liked. Had them in PDF format in about 5 minutes for $40.

Ordered steel in the morning and started the next day.

It's been a lot of fun. Here's a few pictures.

To move the tractor and a piece of equipment or two I figured a 16' car trailer would be about right. Searched the net and found a set of plans I liked. Had them in PDF format in about 5 minutes for $40.

Ordered steel in the morning and started the next day.

It's been a lot of fun. Here's a few pictures.