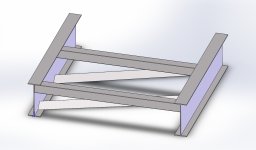

Found a I beam drop 16 x 5.5 x 5/16. Its 10'11'' long and 26 lbs per foot. So working on a land plane build just have a few questions.

blades angled vs straight. Seems like angled blades for gradeing and straight for leveling. So guys with straight blades do you wish they were angled while gradeing ? guys with angled blades wish they were straight while leveling?

If I cut my beam in half ill have 5' 5.5" skids if I back set the blades 5.5" and run them at about 22.5* it would land in the middle of the skid and I would end up with a 5.5' cutting width useing a 6' blade. Does that sound feasible.

I would like to have adjustable cutting depth. How are you tbn guys doing it and what depth increments?

blades angled vs straight. Seems like angled blades for gradeing and straight for leveling. So guys with straight blades do you wish they were angled while gradeing ? guys with angled blades wish they were straight while leveling?

If I cut my beam in half ill have 5' 5.5" skids if I back set the blades 5.5" and run them at about 22.5* it would land in the middle of the skid and I would end up with a 5.5' cutting width useing a 6' blade. Does that sound feasible.

I would like to have adjustable cutting depth. How are you tbn guys doing it and what depth increments?