Hello everyone i just bought a new rear blade ( it seem a little wider than category 1) HF quick hitch on order right will probably be too narrow, Just thinking has anyone ever switched the pins from outside to the inside, would this work? and with this blade

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rear Blade HF Quick hitch too narrow

- Thread starter scrivy69

- Start date

- Views: 8300

-

- Tags

- quick hitch

More options

Who Replied?

/ HF Quick hitch too narrow

#1

RoyJackson

Rest in Peace

- Joined

- Nov 17, 2001

- Messages

- 24,646

- Location

- Bethel, Vermont

- Tractor

- John Deere 4052R Cab,, Deere 855D UTV, Z920A Zero Turn Mower and assorted implements

Don't make any changes until you get your quick hitch.

Right off the bat, it looks like the gussets might be a problem if you reversed those pins.

Once you get that quick hitch, you can make a better determination.

Right off the bat, it looks like the gussets might be a problem if you reversed those pins.

Once you get that quick hitch, you can make a better determination.

KennyG

Super Member

Based on your dimensions, that looks like a Cat 2 blade, not a Cat 1. I know I couldn't get that on my JD 3 point even without the QH on it. What tractor are you using this on?

That looks like a Howse blade like mine and is supposedly a cat 1 but mine wont fit my HF QH either. And turning the pins in wouldn't work on mine.

There is an outfit I just saw a magazine of called agrisupply and they have a QH thats cat 1 and the width is 30 1/4 doesn't say id or od whereas the HF is supposedly (mine is) 27 1/2 id. fwtw

Just one more thing we still have to do the old fashion way standardization my royal Scandinavian rear end. :laughing:

There is an outfit I just saw a magazine of called agrisupply and they have a QH thats cat 1 and the width is 30 1/4 doesn't say id or od whereas the HF is supposedly (mine is) 27 1/2 id. fwtw

Just one more thing we still have to do the old fashion way standardization my royal Scandinavian rear end. :laughing:

I wonder if you could cut the gussets out with a torch? It probably would be strong enough without them? Or you could remove the gussets and weld some 1/4"X1" flat to the outside for reinforcement? However, there still might be another problem. It's hard to tell from the picture; will there be enough room between the pin and the square tubing for the quick hitch lowers to hook the pins if you reverse them to the inside?

RoyJackson

Rest in Peace

- Joined

- Nov 17, 2001

- Messages

- 24,646

- Location

- Bethel, Vermont

- Tractor

- John Deere 4052R Cab,, Deere 855D UTV, Z920A Zero Turn Mower and assorted implements

I wonder if you could cut the gussets out with a torch? It probably would be strong enough without them? Or you could remove the gussets and weld some 1/4"X1" flat to the outside for reinforcement? However, there still might be another problem. It's hard to tell from the picture; will there be enough room between the pin and the square tubing for the quick hitch lowers to hook the pins if you reverse them to the inside?

Those gussets are there to provide strength and stiffness. Angling the blade would put quite a bit of stress in the hitch pin area.

Not advisable to remove those gussets...

allen in texas

Platinum Member

- Joined

- Oct 26, 2007

- Messages

- 919

- Location

- Levelland, TX

- Tractor

- Kubota Grand L 5740, loaded R1's w/640 lbs cast weight, 854 loader

An implement set up properly for a cat 1 quick hitch will be 26 inches wide. then the shoulder on the pins will add about another half inch to that width. The quick hitch if properly built will be 27 inches wide inside the hooks. ( or is it 27.5? I fergit)

A cat two implement is 32 inches wide. Your blade looks to be between those measurements. That is not at all unusual. Close is good enough for a lot of manufactureres

Here is an image of what Cat 1 dimensions are...

http://www.lsuagcenter.com/mcms/web...3C6E2AC/33248/quickhitchdimensionsfromPDF.jpg

A cat two implement is 32 inches wide. Your blade looks to be between those measurements. That is not at all unusual. Close is good enough for a lot of manufactureres

Here is an image of what Cat 1 dimensions are...

http://www.lsuagcenter.com/mcms/web...3C6E2AC/33248/quickhitchdimensionsfromPDF.jpg

Based on your dimensions, that looks like a Cat 2 blade, not a Cat 1. I know I couldn't get that on my JD 3 point even without the QH on it. What tractor are you using this on?

Kenny its going on a JD 2320 i have use almost the widest width, but it fits.

I thought something was strange when i took off my rock rake and then put on the blade.

Those gussets are there to provide strength and stiffness. Angling the blade would put quite a bit of stress in the hitch pin area.

Not advisable to remove those gussets...

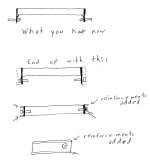

I didn't explain it well enough but that's why I also suggested welding some 1/4" by 1" flat on edge to the outside, above and below the nut. You would go the entire length of the plate that is welded to the square tubing and has the pin mounted in it. In other words, you would basically form that into a channel iron with just enough room to turn the nut. I think that would be just as strong as original if not even a little stronger because it would actually reinforce all the way out to the pin. Again, that is if there is enough room between the pin and the square tubing to allow this.

Attachments

Haywire

Veteran Member

Looks like you can cut an inch or two off the square tube on each side and reweld the cap, pin and gusset back on. Sucks to have to do that to a new implement though.

Ian

Ian

Looks like you can cut an inch or two off the square tube on each side and reweld the cap, pin and gusset back on. Sucks to have to do that to a new implement though.

Ian

That's of course an option but much more work than what I suggested.

from tube to center of pin is 1 5/8in

OK, I think that would probably be too close then, turning the pins to the inside probably isn't going to work.

RoyJackson

Rest in Peace

- Joined

- Nov 17, 2001

- Messages

- 24,646

- Location

- Bethel, Vermont

- Tractor

- John Deere 4052R Cab,, Deere 855D UTV, Z920A Zero Turn Mower and assorted implements

I didn't explain it well enough but that's why I also suggested welding some 1/4" by 1" flat on edge to the outside, above and below the nut. You would go the entire length of the plate that is welded to the square tubing and has the pin mounted in it. In other words, you would basically form that into a channel iron with just enough room to turn the nut. I think that would be just as strong as original if not even a little stronger because it would actually reinforce all the way out to the pin. Again, that is if there is enough room between the pin and the square tubing to allow this.

Yeah, I think I see what you're describing. Rather then two 1/4"x 1" flats, I'd consider a couple short lengths of "C" channel welded all around. He'd have to burn a hole large enough for the nuts though.

However, I still think scrivy69 needs to wait until the QH comes in. It might fit great or he might be best served by returning the rear blade. If his measurements are correct (and I've no doubt they are), that blade seems to be a bit large for a Category 1 (3PH) hook up.

ayelvington

Gold Member

I'm with Roy; wait for your QH.

FYI: I bought a blade from TSC that should have been CAT1, but the welds were sloppy and the yoke was wide. If that's your case, take the blade back as not being compliant with the standard.

It was too late for me, and I eneded up cutting and rewelding the yoke to fit. Not something I really enjoy doing.

FYI: I bought a blade from TSC that should have been CAT1, but the welds were sloppy and the yoke was wide. If that's your case, take the blade back as not being compliant with the standard.

It was too late for me, and I eneded up cutting and rewelding the yoke to fit. Not something I really enjoy doing.

galaxie428

Gold Member

It stinks to have to chop up and weld on a new piece of equipment but I had to do the very same thing with a 72" united box blade to make it fit my HF QH. The brackets for the lower pins were not welded on straight and it would not fit the QH. After a few hours of cutting, grinding and welding on my new shiney red BB I had it fixed.

I don't know why manufactures don't do a better job making their stuff to fit a QH.

I don't know why manufactures don't do a better job making their stuff to fit a QH.

SSdoxie

Elite Member

Hello everyone i just bought a new rear blade ( it seem a little wider than category 1) HF quick hitch on order right will probably be too narrow, Just thinking has anyone ever switched the pins from outside to the inside, would this work? and with this blade

Standard QH is 27.5 inside to pins and 29.5 - 30" outside. Your mount flanges are smack dap in middle of the QH hooks. Your going to need that special 31.5" that was mentioned in earlier post or modify the pin mounts, depends on if wider QH will work on your other attachments.

MJPetersen

Veteran Member

You could add a lot of strength in the lower pin area by making it a captured pin-a pin with supports on both ends. If the QH will fit between the square box and the pin then just a small piece of 1/4" with a 7/8" hole lined up with the existing hole, weld it on about 2" inside the other and get a pin that fits through both. You have a stronger pin area, and have solved your location problem.

I would definitely do what was necessary to make it fit--having a QH is just too handy.

Mike

I would definitely do what was necessary to make it fit--having a QH is just too handy.

Mike

beenthere

Super Star Member

- Joined

- Aug 16, 2001

- Messages

- 18,617

- Location

- Southern Wisconsin, USA

- Tractor

- JD_4x2_Gator, JD_4300, JD_425, JD_455 AWS, added JD_455, JD_110, JD_X485(sold)

As MJP (Mike) said, I'd look at capturing the pins too.

Just a little bit of cut and weld will fab the blade to fit the QH, and it will be worth every bit of effort.

I'd leave it so the pins could be put back in their original spot just in case you have a need or want to sell it (although prolly worth more to have it QH compatible).

Just a little bit of cut and weld will fab the blade to fit the QH, and it will be worth every bit of effort.

I'd leave it so the pins could be put back in their original spot just in case you have a need or want to sell it (although prolly worth more to have it QH compatible).

Here are some similar links:

Quick Hitches

A new month, a new Quick-Hitch thread.

- Replies

- 33

- Views

- 5K