Ken45101

Elite Member

- Joined

- Feb 14, 2009

- Messages

- 3,679

- Location

- southern Ohio

- Tractor

- Kubota M5040, M9540, B21 TLB, B2710, RTV900, JD 325 Skid steer, KX-121-3 mini excavator

MtnViewRanch: That is a serious backblade!!! very nice setup. i was wondering about the hydraulics on there.. i know right now.. when i tilt my blade for say ditching.. its tough to cut through the ground.. just seems like an amazing amount of force pushing back against the hydrauilics. what would it take to blow out either the cylinder or maybe a line.. something like that.. on there? has it ever happend?

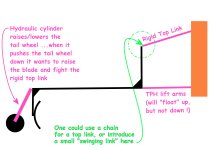

There is no downforce on the 3pt other than the gravity of the implement itself. It will ride up and down as it wants. Once your implement is on the ground, it doesn't matter if you push the lever further or not, there is no additional force and, if need be, the implement will ride up without loading the hydraulics.

Now I guess it's possible to get into a situation where the toplink is extended and the upforce hits the mechanical limits of the 3pt (like backing into a hillside or berm). In that case, if anything is damaged, it's probably going to be that the top link gets bent.

Ken