Thanks,

Yes, the owners manual says different fluid for front versus transmission. Only thing I can think of is that the transmission was overfilled because I got nearly 8 gallons when I drained it. The manual says 27.5 quarts so it must have been overfilled by at least a gallon.

I don't have the owner's manual but will have today. From your pdf I found that the dip stick should not be screwed in to check the level.

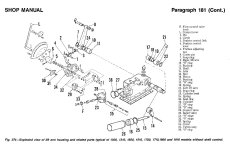

I found another very minor leak on the rigid pipe shown below. The NH site had a detail of this section and it doesn't show an o-ring but only a "fitting assembly" but I'm pretty sure there ought to be an o-ring in there. I'm going to replace this o-ring, providing there is one, and the 2 on the outlet pipe I sucked the oil from. I'll let you know how it goes and thanks again for the help and all the great resources.

Then I may give the tractor a good bath!

Yes, the owners manual says different fluid for front versus transmission. Only thing I can think of is that the transmission was overfilled because I got nearly 8 gallons when I drained it. The manual says 27.5 quarts so it must have been overfilled by at least a gallon.

I don't have the owner's manual but will have today. From your pdf I found that the dip stick should not be screwed in to check the level.

I found another very minor leak on the rigid pipe shown below. The NH site had a detail of this section and it doesn't show an o-ring but only a "fitting assembly" but I'm pretty sure there ought to be an o-ring in there. I'm going to replace this o-ring, providing there is one, and the 2 on the outlet pipe I sucked the oil from. I'll let you know how it goes and thanks again for the help and all the great resources.

Then I may give the tractor a good bath!