pmbutter

New member

There is a lot of contradictory information about which hole to use for the tractor end of the top link. It's confounded by the issue of hydraulic draft control, which some tractors have, as the effect of that draft control is more pronounced at certain holes.

I know the best advice is to RTFM, but my manual (LS R4047) didn't have any info on the subject.

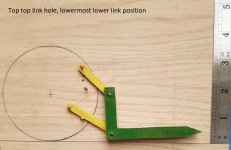

Because I found the geometries hard to visualize, I built myself a little model. It was an amusing diversion, and was fun thinking about Harry Furguson's groundbreaking invention... which originally had two links on the top and one on the bottom. Who knew?! 3 point linkage.* 3 point tractor linkage

There will be some variation from tractor to tractor about where the connection points are relative to each other, but you may find looking at these pictures helps you think about your tractor.

The bottom hole provides the greatest elevation change of the "tail wheel" of my "implement", but it also the greatest angular change relative to the plane of the ground.

The top hole gives the least elevation change of the tail wheel, but better maintains parallelism with the ground.

Hence, I'm thinking the bottom hole is best for something like a landscape rake where you might want to lift it up and out of the way, perhaps with a little more angle so trash drops off the tines.

And a plow ought to be in one of the upper holes, so it's still at a proper working angle, regardless of its depth.

Happy Spring, everyone!

I know the best advice is to RTFM, but my manual (LS R4047) didn't have any info on the subject.

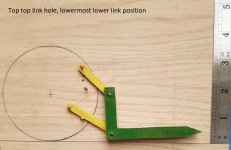

Because I found the geometries hard to visualize, I built myself a little model. It was an amusing diversion, and was fun thinking about Harry Furguson's groundbreaking invention... which originally had two links on the top and one on the bottom. Who knew?! 3 point linkage.* 3 point tractor linkage

There will be some variation from tractor to tractor about where the connection points are relative to each other, but you may find looking at these pictures helps you think about your tractor.

The bottom hole provides the greatest elevation change of the "tail wheel" of my "implement", but it also the greatest angular change relative to the plane of the ground.

The top hole gives the least elevation change of the tail wheel, but better maintains parallelism with the ground.

Hence, I'm thinking the bottom hole is best for something like a landscape rake where you might want to lift it up and out of the way, perhaps with a little more angle so trash drops off the tines.

And a plow ought to be in one of the upper holes, so it's still at a proper working angle, regardless of its depth.

Happy Spring, everyone!

Last edited: