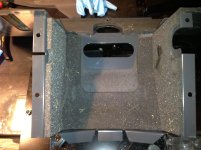

You're right Waxman, there is a slight outline in the foam where that tranny mounting plate is touching the foam. I honestly don't believe the design is for that floor plate to sit on the tranny housing, but I do believe your're correct that over time, it will probably sag.

I'm going to try something a little different. The rubber isolation mat I have in my shop is 1/2" thick, and the foam under that pan is only 3/8" thick. It looks like the area that is touching that tranny plate got compressed 1/8"-3/16". The floor mat I got to go under the rubber mat is 1/2" thick overall, with 1/8" thick vinyl adhered to a high density foam. I think I'm going to give that a try vs a rubber mat and see how that works. That way, at least for a while, the tranny plate is still not supporting the floor plate.

In time, I suspect the foam backer will compress, but I'm thinking it would take a while for the vinyl to rub all the way through if the floor pan continued to sag. I guess I'll find out somewhere down the road, and expect it could be quite a while, but at that point, I may need to install a rubber pad to support the floor pan. Until that time, the stuff I plan to use should give me a decent sound buffer, since the floor plate won't be supported by the tranny plate.

I'm only considering doing it this way because I want to keep those 2 steel parts separated for as long as possible. If it took 700 hours and 230# to get those 2 plates rubbing the way they did, then I think I have a little time to go before my sub 170# a** can do enough damage. I kind of want to see what "pans" out (pardon the pun). It'll be a good experiment, and hopefully by the time I may have to address it, I won't mind pulling a few of the floor plates apart to fix it.

At that point, you can say "I told you so".

I pulled one fender off, since I plan to coat the wheel well with liquid sound deadening. Didn't get warm enough to do it outside today, so I left the other fender on. I plan to also coat the outside of the rear panel that holds the tool box, since that's like a snare drum also. May do that piece while it's on the tractor, so that way I can do one fender, re-install it, and then pull the other fender. Fenders will definitely be easier to prep & coat while off the tractor.

Just hoping we don't get a big snowstorm before I finish. Waiting on some more foam to show up that I want to stuff into various crevices, and a few channels that I found, and I don't know if that will even make it before the weekend. And of course, after looking like it was going to be a nice weekend, now it seems a storm may be moving in.

Oh, and good to know the rubber mounts are still in good shape with nearly 800 hours. :thumbsup: