jodebg

Platinum Member

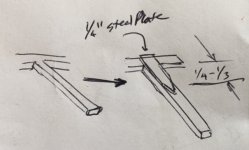

Working on plans to build a set of 3PH forks.

For the tines, the plans call for 2 x 2x 1/4" tubular steel- 43" long.

They have been load tested to over 2000lb lift capacity in this design.

I was considering using 3" x 1.5" x 3/16" inplace of the 2x2 called for in the plans.

This seems to be a better dimension for tines.

The steel guys did not know if the 3 x 1.5" was available in 1/4" thickness?

My question is how strong is the 3 x 1.5" tubular steel compared to the 2 x 2 x 14" sotck?

For the tines, the plans call for 2 x 2x 1/4" tubular steel- 43" long.

They have been load tested to over 2000lb lift capacity in this design.

I was considering using 3" x 1.5" x 3/16" inplace of the 2x2 called for in the plans.

This seems to be a better dimension for tines.

The steel guys did not know if the 3 x 1.5" was available in 1/4" thickness?

My question is how strong is the 3 x 1.5" tubular steel compared to the 2 x 2 x 14" sotck?