You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New to me TC29D cranks & won’t start

- Thread starter CalienteJohn

- Start date

- Views: 41520

-

- Tags

- new start tc29d won't start

More options

Who Replied?

/ New to me TC29D cranks & won’t start

#141

If we are being pessimistic, I wouldn't order any rebuild parts until after I tore it down. No way of knowing what you will need until you get there.Delays with the injectors being rebuilt and delays with me getting to the valve adjustments. Been SUPER BUSY

Anything else besides check the distilled water in battery?

Should I order a head gasket, head’s gotta come off for sure after injectors attempt right ?

I’m still optimistic that it will pop once it has more than one working injector.

K5lwq

Elite Member

- Joined

- Aug 6, 2017

- Messages

- 4,918

- Location

- Mineola, TX

- Tractor

- Kioti LK2554, Branson 4815C, Satoh Beaver, Speedex

I would not start anything else until you get the injectors in. Hopefully it fires, then you can do some test before deciding what is next. Distilled water in battery and battery on a charger is about all you can do right now.

aircommuter

Platinum Member

- Joined

- Nov 26, 2012

- Messages

- 707

- Location

- coulterville,ca

- Tractor

- case 570lxt, JCB 1550B, Gradall 534c, Hyster C612B,Ford 445A

Been up there on a road that followed the river. Little windy, restaurant seemed like a hangout for Kern county sheriff. Old school house, rocky soil? A siren for the dam? Just what I remember from about 10 years ago. I am in Greeley Hill, not really a county recognized place. Sign says elevation: JUST RIGHT. Population: FRIENDLY. While I am 7 miles from Coulterville that’s the zip code.Near lake Isabella

Havilah CA

Central foothills is exactly how I’d describe it here

High enough altitude we get snow but enjoyable amounts of it is all. Horse property couple of cows 40 acres in the family here .

CalienteJohn

Bronze Member

- Joined

- Apr 18, 2024

- Messages

- 56

- Tractor

- TC29D

Rebuilt injectors

Probably should have just sent em to “THE PUMP GUY” here for a pro job but my local guy did a fair job it appears

Pop test repeat w/ rebuilt inj will be available soon

Probably should have just sent em to “THE PUMP GUY” here for a pro job but my local guy did a fair job it appears

Pop test repeat w/ rebuilt inj will be available soon

Attachments

CalienteJohn

Bronze Member

- Joined

- Apr 18, 2024

- Messages

- 56

- Tractor

- TC29D

HAPPY MEMORIAL DAY ESPECIALLY TO THOSE WHO SERVED!!!

Pop test made such a diesel fog it was comical definitely all 3 working LOTS better

Pop test made such a diesel fog it was comical definitely all 3 working LOTS better

thepumpguysc

Elite Member

U see the difference.??

The “mist” is what catches fire in the cylinders..

Hope to hear, ITS RUNNING

shortly..

The “mist” is what catches fire in the cylinders..

Hope to hear, ITS RUNNING

shortly..

CalienteJohn

Bronze Member

- Joined

- Apr 18, 2024

- Messages

- 56

- Tractor

- TC29D

I wish I could say ITS RUNNING

BUT ITS NOT. No joy

GPs wired and everything torqued to spec

BUT ITS NOT. No joy

GPs wired and everything torqued to spec

Last edited:

thepumpguysc

Elite Member

Sounds like ur gonna need a starter soon..

And you’ve bled the air out all the way to the injectors.?? And THEN tighten them up..

And you’ve bled the air out all the way to the injectors.?? And THEN tighten them up..

LouNY

Super Star Member

- Joined

- Jul 4, 2015

- Messages

- 14,418

- Location

- Greenwich, NY

- Tractor

- Branson 8050, IH 574, Oliver 1550 Diesel Utility (traded in on Branson) NH 8160. Kioti CK2620SECH

Were you at least getting some white smoke out the exhaust?

With the compression numbers you had I'm not really surprised.

But now your injectors are ready when you get the block back in shape.

With the compression numbers you had I'm not really surprised.

But now your injectors are ready when you get the block back in shape.

the old grind

Super Member

- Joined

- Jul 21, 2012

- Messages

- 5,308

- Location

- Mid-Michigan

- Tractor

- NH T-1520 HST, NH TC33DA HST, Case DX26 HST, .Terramite T5C, . NH L785

Sorry this is so long. Are the GPs wired to be on continuously, or cycled several times before/between cranking? I've had to do the latter 3-4 times to start little red in 65 degree weather after sitting less than a week. Loose lash or swarf on valves or seats can impair proper compression.

A leak down test could clear that up if we haven't done that by now. With any leak (all three cyls? maybe) slow cranking makes thing worse. I'd hot wire the GPs and jump the battery from a running vehicle If that's not done already. (starter brushes worn? commutator dirty?)

Cam tuning/timing, porting, etc flows air the best at peak torque RPM, usually 1600 with our engines. Better flow leads to higher BMEP, so more heat to light the fuel. IMO 600 rpm(?) won't help our compression test or our chance of ignition. My CUTs run lumpy at 800 rpm and I 'idle' them at 1200-1400. (No load = min gph burned at any)

I'm stuck hoping that some things will shake loose after say minutes of run time, and I'm still not wanting to take more apart just yet. Also, last night on a long shot I wondered if a PO misread what the dirty injectors caused and removed the pump, then reinstalled it out of time to be sold. Any provenance with this one?

A leak down test could clear that up if we haven't done that by now. With any leak (all three cyls? maybe) slow cranking makes thing worse. I'd hot wire the GPs and jump the battery from a running vehicle If that's not done already. (starter brushes worn? commutator dirty?)

Cam tuning/timing, porting, etc flows air the best at peak torque RPM, usually 1600 with our engines. Better flow leads to higher BMEP, so more heat to light the fuel. IMO 600 rpm(?) won't help our compression test or our chance of ignition. My CUTs run lumpy at 800 rpm and I 'idle' them at 1200-1400. (No load = min gph burned at any)

I'm stuck hoping that some things will shake loose after say minutes of run time, and I'm still not wanting to take more apart just yet. Also, last night on a long shot I wondered if a PO misread what the dirty injectors caused and removed the pump, then reinstalled it out of time to be sold. Any provenance with this one?

Mud2Money

Silver Member

That engine for sure has a gallop when cranking. The injectors spray awesome now. I was just thinking like mentioned above. The injection pump timing could be out.

thepumpguysc

Elite Member

The timing is set with shims UNDER the pumps mounting flange.. so changing is unlikely..

Have u just glossed over the 100 psi compression numbers.??

Have u just glossed over the 100 psi compression numbers.??

K5lwq

Elite Member

- Joined

- Aug 6, 2017

- Messages

- 4,918

- Location

- Mineola, TX

- Tractor

- Kioti LK2554, Branson 4815C, Satoh Beaver, Speedex

That engine sure sounds like it wants to fire off. It needs to turn over a little faster and I think it would. A good set of jumper cables from a running truck might do the trick.

There isn’t a decompression valve on this tractor is there? I’m pretty sure not but could be wrong.

There isn’t a decompression valve on this tractor is there? I’m pretty sure not but could be wrong.

CalienteJohn

Bronze Member

- Joined

- Apr 18, 2024

- Messages

- 56

- Tractor

- TC29D

Had to take a few frustrated days break to weed whack every spare minute here around property since fire season is upon us.

I’ve tried to do everything mentioned here

Check on bleed lines up to injectors one at a time and on starter it’s been cranked long and heavy I’m assuming at this point

Yes getting white gray and black smoke this last time and at the end of new video it definitely tried more then ever before to start.

No the pump has not obviously been taken off recently from what I see

I’ve adjusted throttle up and down when trying to start

I’ve cycled glow plugs up to four times before starting attempt and yes once or twice cycle in between starting attempts. Should I “hot wire them” a time while cranking?

The only thing mentioned I haven’t done is actually adjusting the valves I checked for gross miss adjustment in videos posted above was all…

Have it hooked in test video to a 1993 Jeep Cherokee with 160 amp alternator and a 800 cold cranking amp battery..

Still no joy..

I’ve tried to do everything mentioned here

Check on bleed lines up to injectors one at a time and on starter it’s been cranked long and heavy I’m assuming at this point

Yes getting white gray and black smoke this last time and at the end of new video it definitely tried more then ever before to start.

No the pump has not obviously been taken off recently from what I see

I’ve adjusted throttle up and down when trying to start

I’ve cycled glow plugs up to four times before starting attempt and yes once or twice cycle in between starting attempts. Should I “hot wire them” a time while cranking?

The only thing mentioned I haven’t done is actually adjusting the valves I checked for gross miss adjustment in videos posted above was all…

Have it hooked in test video to a 1993 Jeep Cherokee with 160 amp alternator and a 800 cold cranking amp battery..

Still no joy..

Last edited:

CalienteJohn

Bronze Member

- Joined

- Apr 18, 2024

- Messages

- 56

- Tractor

- TC29D

Hot wired GPs to work while cranking. No improvement even while working throttle position slowly.

Searching for rings and gaskets at this point

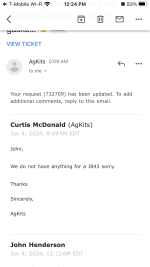

One response from agkits.com they don’t carry anything

Waiting on a response from reliance and another company but it seems only places that carry these are over seas…

Any parts website recommendations? Local Dealer or no?

I think I’m leaning towards buying new rings and gaskets once I tear it apart to see nothing is significantly worn.

Do an in frame as some of you’ve said. Then it should at least run well enough to test everything else and maybe well enough to just work for us a few times a month as is.

Engine is a J843 if anyone can find something they would recommend specifically

Thank you again everyone

Searching for rings and gaskets at this point

One response from agkits.com they don’t carry anything

Waiting on a response from reliance and another company but it seems only places that carry these are over seas…

Any parts website recommendations? Local Dealer or no?

I think I’m leaning towards buying new rings and gaskets once I tear it apart to see nothing is significantly worn.

Do an in frame as some of you’ve said. Then it should at least run well enough to test everything else and maybe well enough to just work for us a few times a month as is.

Engine is a J843 if anyone can find something they would recommend specifically

Thank you again everyone

Attachments

Last edited:

Molalla1

Super Member

CJ as you know it's a Shibura . . . you should be able to cross reference your engine parts?Searching for rings and gaskets

One response from agkits.com they don’t carry anything

Waiting on a response from reliance and another company but it seems only places that carry these are over seas…

Any parts website recommendations? Local Dealer or no?

I think I’m leaning towards buying new rings and gaskets once I tear it apart to see nothing is significantly worn.

Do an in frame as some of you’ve said. Then it should at least run well enough to test everything else and maybe well enough to just work for us a few times a month as is.

Engine is a J843 if anyone can find something they would recommend specifically

Thank you again everyone

LouNY

Super Star Member

- Joined

- Jul 4, 2015

- Messages

- 14,418

- Location

- Greenwich, NY

- Tractor

- Branson 8050, IH 574, Oliver 1550 Diesel Utility (traded in on Branson) NH 8160. Kioti CK2620SECH

You used to be able to order rings by the diameter, width and thickness.

https://size.name/en/catalog/piston_ring_sets

https://size.name/en/catalog/piston_ring_sets

Mud2Money

Silver Member

I see shibaru N843 rebuild kits all over. Not sure if it’s the same as the j843. Sounds like the N designation is just naturally aspirated. Many kits list the part numbers. You could get the part numbers and cross reference.

Here are some similar links:

- Replies

- 24

- Views

- 3K