Kodiak45

Gold Member

- Joined

- Feb 11, 2013

- Messages

- 320

- Location

- SC

- Tractor

- long 2460 - belarus 250 - JD 4230 - Kioti DK40SE

Found the spool of wire I was missing….

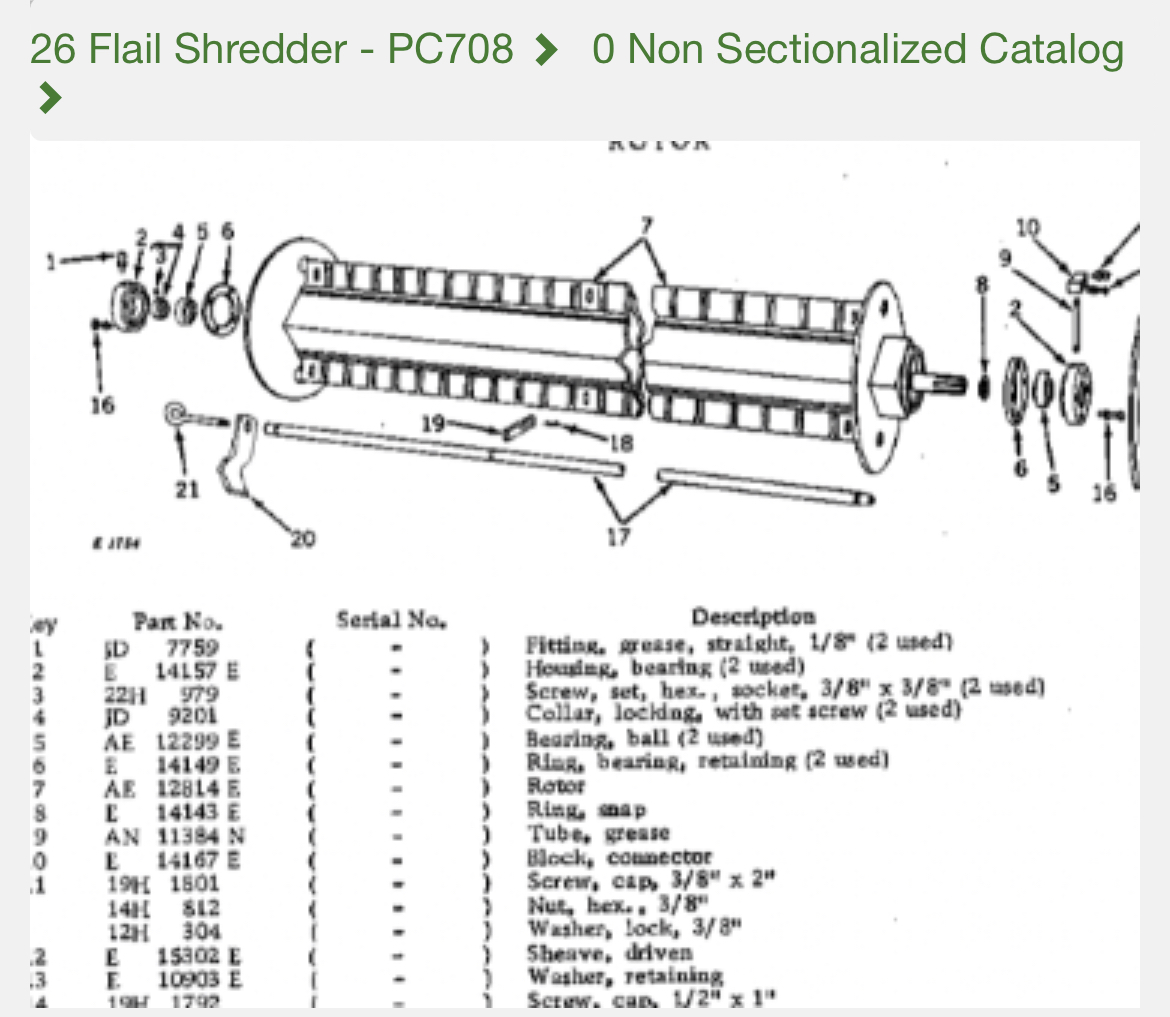

I was cutting nicely until I found my missing spool of fence wire. After untangling the mess, here is what I’m left with. Looks like I need parts 5,6,8.

Will I be able to get this off with a standard bearing puller?

Any tips would be appreciated as this is my first bearing replacement.

It looks like I can only find aftermarket parts for this JD 26.

I was cutting nicely until I found my missing spool of fence wire. After untangling the mess, here is what I’m left with. Looks like I need parts 5,6,8.

Will I be able to get this off with a standard bearing puller?

Any tips would be appreciated as this is my first bearing replacement.

It looks like I can only find aftermarket parts for this JD 26.