Its a problem with an

bx1830 (500hrs on the clock, garage kept and babied) that I posted about a few weeks back. I don't have power under load and get a chattering that sounds like the HST is starved.

I first checked the transmission oil level, it was fine, went ahead and changed the transmission oil, filter and cleaned the screen as it was due. They all looked fine and I used super UDT2 as directed. This didn't give any positive result.

Next I checked the pump pressure at the front end loader, it was actually about 100psi high so I removed a shim and got it within spec (about 1800 psi). I also left the tester on and drove the tractor under load and then actuated the loader control during the chatter and got a reading of just over 1800 psi, so it seems the pump is keeping up under load.

I then got the parts to check the charge pressure and the forward motion circuit pressure. The charge pressure was at the low end of the range around 45 psi (range per WSM is 42-71) at a standstill, and when I drove the tractor up a hill to get the chatter going the charge pressure dropped to around 20psi or less.

I also checked the forward pressure under load (fyi, chatter is in forward or reverse), and got a max of 1100 psi. The high pressure relief per the WSM is 1991 psi.

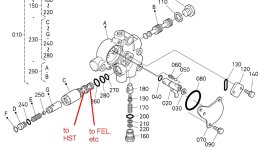

So it seemed I wasn't getting oil to the HST in my very amateur opinion. I wondered about the flow priority valve as it splits between the implements in one route, and the power steering/HST in the other route. I took it apart and cleaned it, replaced it, and it didn't help. I also cleaned and inspected the charge relief and PTO relief although they looked fine.

My thought now was that the priority valve may be acting up. If you look at the design its spring loaded with the idea that if the pressure drops it blocks the flow to the implements. On the flip side under high pressure I wondered if it would push the plunger far enough (i.e. with a weak spring), to block the flow to the HST and give it all to the implements (under load chattering the FEL has tons of power).

As an aside the HST, engine, drive shaft all sound fine crusing along under low load. Under heavier load, i.e. a hill or pushing into a mulch pile with the loader, the HST chatters away and has no power while the engine doesn't bog one bit.

Right now I ordered a new priority relief valve and a new spring set for the charge relief valve and will give it a whirl.

Thanks to both of you for your help and I'll let you know how it turns out. The kubota dealer has been very helpful and said they would have done what I did, and are stumped at this point as well.

My question about the pressure coming out of the power steering was I looked at the hydraulic schematic and it shows high pressure to the power steering, and low coming out. Perhaps because its dumping to the chamber around the HST and then the charge pressure relief dumps the flow to maintain lower psi?