dfkrug

Super Member

- Joined

- Feb 3, 2004

- Messages

- 7,665

- Location

- Santa Cruz Mtns, CA

- Tractor

- 05 Kioti CK30HST w/ Prairie Dog backhoe, XN08 mini-X

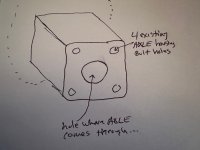

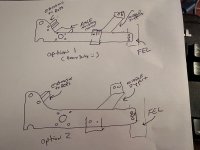

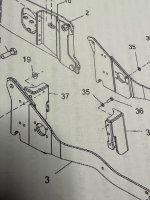

Yeah, it looks like the Woods subframe does use those holes. Is your axle housing made of cast steel or aluminum?I "think" the woods sub frame 1020800 utilizes four tapped holes on the end of the axel housing on each side.

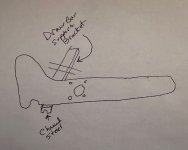

The parts diagram also seems to imply that your wheel hubs are easily removeable, with spline shafts or similar. That way you fit the axle thru the hole in your subframe.

I would stick with a smaller hoe (6.5') for your size B tractor.

Last edited: