Sodo

Elite Member

- Joined

- Apr 21, 2012

- Messages

- 3,311

- Location

- Cascade Mtns of WA state

- Tractor

- Kubota B-series & Mini Excavator

And then the more I think about it..... Just go spend your money on a mower that does what you want it to do and that you can still buy parts for. I know!! I don't like to throw stuff away either but this to me looks like a repair that in the end is just going to break again. There is just too much heavy stuff being thrown around inside that gearbox. That's my thoughts.

I hear you, but keeping the hope alive.

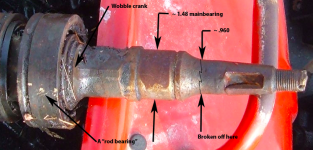

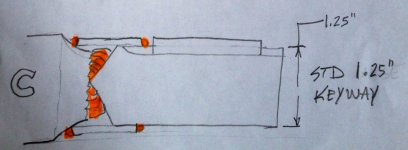

I'm stuck for the moment because the wobble crank is being kind of a bugger. Until it comes out, I can't proceed. Heres a pic of a plate on the mower showing the wobble crank business. It does a bunch of monkey-motion to balance out the shaking of the sickle bar. Massey-Ferguson calls it "Dyna Balance".

I've found a sheave (not adjustable speed) for $35, browning style hub $20, shaft for $30, and a belt for $20 = $110. Welding is easy for me but certainly it will take some head-scratching which I'm not against.

If I can get the wobble crank out, I'll weld it myself and put it back together. If it breaks, THEN I'll scrap it. I already have a field mower but want to know if a sickle mower works better. I want to mow knapweed without disturbing the grass so much. I want to extend the mower under bushes and off the roadside. I know what the field mower does, it makes a mess that takes 2 weeks to look nice, and also it only follows the tractor, and can't reach under bushes and trees.

Of course after I bought this broken one for $150 some working mowers pop upfor $400 now, but they look kinda worn out. Mine's in nice condition except for one very important part.

Attachments

Last edited: