TimberXX

Platinum Member

- Joined

- Feb 4, 2005

- Messages

- 827

- Location

- Bergen County, NJ

- Tractor

- BCS 770 Italian 2 Wheel Tractor, Grillo 107d, BCS 853, Deere x350, Deere x730

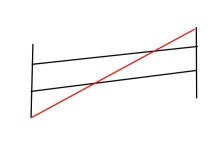

So I bought a front broom, unfortunately it is bent pretty bad, see attached.

What's the best way to Bend it back?

Can't use heat, too many pivoting bushings.

I was thinking a jack, but I can't figure it out

Any thoughts how to bend it back?

What's the best way to Bend it back?

Can't use heat, too many pivoting bushings.

I was thinking a jack, but I can't figure it out

Any thoughts how to bend it back?