polemidis

Gold Member

Hello to the community. I just bought a tractor last week, and I am so excited! I quick realized the need for a grapple. I have 60ac of forest that need heavy thinning and I also need it for loading the firewood.

My apologies to my ignorance, my experience with tractors is only 1 week. Thats the first reason I am reaching to to you guys, because I need your input, feedback and critisism.

The 2nd and MOST important reason is that I am willing to offer my time in order to develop Open Source designs for the public benefit. I cannot afford to pay $1800 for a new grapple, and I bet there are so many with that "limitation" out there. I tried to buy some plans for my own use but noone was willing to sell me any plans or provide any help, so I spent a few hours today prototyping. Hopefully in a few weeks (months?) everybody can make his own grapple keeping the cost 3x below the commercial models. Later on we can start other tools also. Wouldn't be cool to have a repository of Open Source Implements??

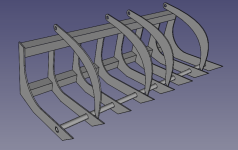

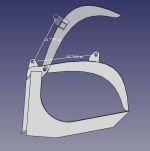

Anyway, one step at a time, this is the result so far. Later on I will add a link of the CAD file for anyone that wishes to contribute, until then if anyone wants it plz PM me to sent it to you.

Wish me luck, and feel free to comment if you have anything useful to say. The idea is that anyone can take the plans for FREE and build its own tool. By letting the plans open source hopefully soon we can improve the design by a lot!

My apologies to my ignorance, my experience with tractors is only 1 week. Thats the first reason I am reaching to to you guys, because I need your input, feedback and critisism.

The 2nd and MOST important reason is that I am willing to offer my time in order to develop Open Source designs for the public benefit. I cannot afford to pay $1800 for a new grapple, and I bet there are so many with that "limitation" out there. I tried to buy some plans for my own use but noone was willing to sell me any plans or provide any help, so I spent a few hours today prototyping. Hopefully in a few weeks (months?) everybody can make his own grapple keeping the cost 3x below the commercial models. Later on we can start other tools also. Wouldn't be cool to have a repository of Open Source Implements??

Anyway, one step at a time, this is the result so far. Later on I will add a link of the CAD file for anyone that wishes to contribute, until then if anyone wants it plz PM me to sent it to you.

Wish me luck, and feel free to comment if you have anything useful to say. The idea is that anyone can take the plans for FREE and build its own tool. By letting the plans open source hopefully soon we can improve the design by a lot!