You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Grapple project OPEN SOURCE

- Thread starter polemidis

- Start date

- Views: 53417

More options

Who Replied?

/ Grapple project OPEN SOURCE

#41

Also, look up "sum of moments around a point".

You will mostly be avoiding having to get into "beam bending moment and shear diagrams" by copying existing designs, building them, and fixing what breaks. And the lessons stick better.

You will mostly be avoiding having to get into "beam bending moment and shear diagrams" by copying existing designs, building them, and fixing what breaks. And the lessons stick better.

I'll assume you simply misquoted. The distance between the pins isn't the problem exactly. I'll let you correctly describe what needs changed.

Sorry guys my English is not my mother language. I mean I will increase the distance between the base pin and the pin that pivots the grapple. So the force will by applied with bigger angle.

Or in other words I will increase the distance between the pivot point and the l line that passes between the cylinder pins. Did I pass the test??

I know that my lack of knowledge gives you comfort (I am just joking), but I do not qualify not even as a user yet (21hours on a tractor in my lwhole life

Btw, what is a desent clamping force in a grapple that a 40hp tractor should have? I will do the calculations (Middle school physics if I recall!!!!) to get that force

ovrszd

Epic Contributor

- Joined

- May 27, 2006

- Messages

- 33,727

- Location

- Missouri

- Tractor

- Kubota M9540, Ford 3910FWD, Ford 555A, JD2210

I'd rather let LD1 explain this, he's much better versed than I. I tend to talk in layman's terms. But I'll give it a go and he or others can feel free to add what I miss.

My point about the amount of cylinder stroke to open/close the claw has little to do with the distance between the two cylinder pins in one position. But it has everything to do with the difference in distance between the cylinder pins when the claw is open versus that distance when the claw is closed.

Here's where I fail verbally. Any tractor has a given hydraulic capacity. That's determined by GPM (gallons per minute) of flow and PSI (pounds per square inch) of maximum pressure. To result in greater force the amount of fluid required to complete the action needs to increase.

This can be accomplished in two ways. Increase the bore diameter of the cylinder or increase the distance of cylinder travel to complete the action. You don't have space for a large diameter cylinder. So you must design the triangle mentioned above to increase the cylinder travel length. Your design of 4" cylinder travel to complete the action isn't enough when using a 2" or 2.5" bore diameter.

My homemade grapple has nil clamping force when the claws are wide open. That clamping force increases dramatically as the claw closes peaking in the last inch of movement. I wasn't smart enough to design that into the plan. It just happened that way. If that situation were reversed my grapple would be worthless. I use 8" of cylinder travel.

My point about the amount of cylinder stroke to open/close the claw has little to do with the distance between the two cylinder pins in one position. But it has everything to do with the difference in distance between the cylinder pins when the claw is open versus that distance when the claw is closed.

Here's where I fail verbally. Any tractor has a given hydraulic capacity. That's determined by GPM (gallons per minute) of flow and PSI (pounds per square inch) of maximum pressure. To result in greater force the amount of fluid required to complete the action needs to increase.

This can be accomplished in two ways. Increase the bore diameter of the cylinder or increase the distance of cylinder travel to complete the action. You don't have space for a large diameter cylinder. So you must design the triangle mentioned above to increase the cylinder travel length. Your design of 4" cylinder travel to complete the action isn't enough when using a 2" or 2.5" bore diameter.

My homemade grapple has nil clamping force when the claws are wide open. That clamping force increases dramatically as the claw closes peaking in the last inch of movement. I wasn't smart enough to design that into the plan. It just happened that way. If that situation were reversed my grapple would be worthless. I use 8" of cylinder travel.

LD1

Epic Contributor

Do the math with the angles I mentioned, and try to get as long of a stroke as possible.

Think of it this way......It dont matter if you use a 4", 6" or 10" cylinder.

The distance the grapple must travel from full open to full closed is gonna be the same. So if that given distance can be accomplished with a 4" cylinder.....you have a clamp force of x.

If you can squeeze a 8" stroke cylinder in there of the same bore diameter (same hydraulic force acting on the grapple) You have essentially doubled your mechanical advantage. So thats like going from a 2" cheater pipe on your wrench to a 4' cheater and still applying the same force.

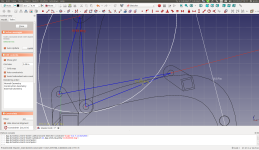

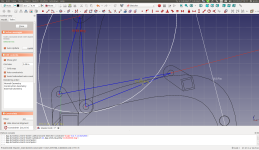

If you look at your design and draw the triangle....it looks like maybe a 7.5 degree mounting angle for the cylinder looking at the second drawing. I am sure you can confirm that with the software you are using.

Most grapples us a 2" bore cylinder, and most tractors run ~2500psi. So that cylinder is capable of pushing with a force of 7850 lbs.

But that cylinder mounted on a 7.5 degree angle....only ~1000 lbs of force trying to close the grapple.....the rest of the force is trying to rip the whole thing apart. Now since the cylinder mount is about half way back the grapple lid....you can cut that in half yet again. and you will have a meager 500# of bite force. Is that enough to "contain" a log or some brush....sure. Is that enough to clamp a rock or clamp anything and actually rely on the clamp power to hold.....absolutely not.

Think of it this way......It dont matter if you use a 4", 6" or 10" cylinder.

The distance the grapple must travel from full open to full closed is gonna be the same. So if that given distance can be accomplished with a 4" cylinder.....you have a clamp force of x.

If you can squeeze a 8" stroke cylinder in there of the same bore diameter (same hydraulic force acting on the grapple) You have essentially doubled your mechanical advantage. So thats like going from a 2" cheater pipe on your wrench to a 4' cheater and still applying the same force.

If you look at your design and draw the triangle....it looks like maybe a 7.5 degree mounting angle for the cylinder looking at the second drawing. I am sure you can confirm that with the software you are using.

Most grapples us a 2" bore cylinder, and most tractors run ~2500psi. So that cylinder is capable of pushing with a force of 7850 lbs.

But that cylinder mounted on a 7.5 degree angle....only ~1000 lbs of force trying to close the grapple.....the rest of the force is trying to rip the whole thing apart. Now since the cylinder mount is about half way back the grapple lid....you can cut that in half yet again. and you will have a meager 500# of bite force. Is that enough to "contain" a log or some brush....sure. Is that enough to clamp a rock or clamp anything and actually rely on the clamp power to hold.....absolutely not.

ovrszd

Epic Contributor

- Joined

- May 27, 2006

- Messages

- 33,727

- Location

- Missouri

- Tractor

- Kubota M9540, Ford 3910FWD, Ford 555A, JD2210

Do the math with the angles I mentioned, and try to get as long of a stroke as possible.

Think of it this way......It dont matter if you use a 4", 6" or 10" cylinder.

The distance the grapple must travel from full open to full closed is gonna be the same. So if that given distance can be accomplished with a 4" cylinder.....you have a clamp force of x.

If you can squeeze a 8" stroke cylinder in there of the same bore diameter (same hydraulic force acting on the grapple) You have essentially doubled your mechanical advantage. So thats like going from a 2" cheater pipe on your wrench to a 4' cheater and still applying the same force.

If you look at your design and draw the triangle....it looks like maybe a 7.5 degree mounting angle for the cylinder looking at the second drawing. I am sure you can confirm that with the software you are using.

Most grapples us a 2" bore cylinder, and most tractors run ~2500psi. So that cylinder is capable of pushing with a force of 7850 lbs.

But that cylinder mounted on a 7.5 degree angle....only ~1000 lbs of force trying to close the grapple.....the rest of the force is trying to rip the whole thing apart. Now since the cylinder mount is about half way back the grapple lid....you can cut that in half yet again. and you will have a meager 500# of bite force. Is that enough to "contain" a log or some brush....sure. Is that enough to clamp a rock or clamp anything and actually rely on the clamp power to hold.....absolutely not.

Yeah,,,,, what he said.......

Even the best calculations can steer you wrong. Sometimes you just have to cut metal and see what happens.

For example, here is the original version of my garden tractor front loader:

Here is the redesign I came up with later:

Both versions used scrounged cylinders in nonstandard sizes. One has far fewer parts and weighs 70 lbs. less. This is also why I say sometimes you throw away half your materials. Sometimes whole parts of your design have to be cut off and set to one side.

70 lbs. at the far end of the loader boom makes a lot of difference to the operating performance of the machine. For both, the calculations on the range of motion and dump force on the actual bucket were correct. It is not always the things you measure and calculate that will be a problem, but aspects you did not even know to consider.

Sometimes what breaks won't even be on the parts you make. (my loader is now on a heavier tractor, and has had yet other things fixed and modified)

For straight out saving money and getting the job done, though, this was the actual best solution:

I finished building my machine because I am stubborn, and it was fun (for me, not everyone finds this type of design iteration work fun).

Have you had a chance to watch videos of people using a grapple to do what you are thinking of doing?

For example, here is the original version of my garden tractor front loader:

Here is the redesign I came up with later:

Both versions used scrounged cylinders in nonstandard sizes. One has far fewer parts and weighs 70 lbs. less. This is also why I say sometimes you throw away half your materials. Sometimes whole parts of your design have to be cut off and set to one side.

70 lbs. at the far end of the loader boom makes a lot of difference to the operating performance of the machine. For both, the calculations on the range of motion and dump force on the actual bucket were correct. It is not always the things you measure and calculate that will be a problem, but aspects you did not even know to consider.

Sometimes what breaks won't even be on the parts you make. (my loader is now on a heavier tractor, and has had yet other things fixed and modified)

For straight out saving money and getting the job done, though, this was the actual best solution:

I finished building my machine because I am stubborn, and it was fun (for me, not everyone finds this type of design iteration work fun).

Have you had a chance to watch videos of people using a grapple to do what you are thinking of doing?

I only know practical application. They know "why".

Sometimes the why is meaningless without knowing more about the "the theory is this, but when you actually use them...what everyone does is this" that you only get from a lifetime of running machines. You really need both, or a team of people that collectively know both.

There was a guy on another forum who made all his machines using "cardboard assisted design."

He would make all his parts full size, on the machine, with light weight boards, cardboard, and nuts and bolts. For a cylinder, he would have two boards, one with holes at the "retracted" distance, and one with holes at the "extended" distance. He would take notes with a marker directly on the parts. You can learn stuff from doing that that you might miss other wise, like "will the bucket hit the hood when the boom goes up?"

Computers are fun, but they are not always the best way, or the only way.

He would make all his parts full size, on the machine, with light weight boards, cardboard, and nuts and bolts. For a cylinder, he would have two boards, one with holes at the "retracted" distance, and one with holes at the "extended" distance. He would take notes with a marker directly on the parts. You can learn stuff from doing that that you might miss other wise, like "will the bucket hit the hood when the boom goes up?"

Computers are fun, but they are not always the best way, or the only way.

Another example:

I had one set of pins that I did not have grease fittings on. Sure enough, at some point later I was working with jacks, chain, and torches after it stopped working so I could get it apart, drill, thread and add fittings.

Speaking of fittings, they can either go into the side of a bushing, or into the end of a pin with a hole drilled down the middle to a cross-drilled hole that comes out in the middle of the bushing. But one way or the other, every part that moves should have a way to get grease. If you look at the other parts of your tractor, you should see this.

I had one set of pins that I did not have grease fittings on. Sure enough, at some point later I was working with jacks, chain, and torches after it stopped working so I could get it apart, drill, thread and add fittings.

Speaking of fittings, they can either go into the side of a bushing, or into the end of a pin with a hole drilled down the middle to a cross-drilled hole that comes out in the middle of the bushing. But one way or the other, every part that moves should have a way to get grease. If you look at the other parts of your tractor, you should see this.

ovrszd

Epic Contributor

- Joined

- May 27, 2006

- Messages

- 33,727

- Location

- Missouri

- Tractor

- Kubota M9540, Ford 3910FWD, Ford 555A, JD2210

Sometimes the why is meaningless without knowing more about the "the theory is this, but when you actually use them...what everyone does is this" that you only get from a lifetime of running machines. You really need both, or a team of people that collectively know both.

Nicely stated.

No offense intended in this statement. All designers need to also be operators/fabricators.

Thank you guys. Your comments directed me to what to research. Feel free to correct me if I am wrong, no offense taken on construtive critisim.

So, you end up with 7500lb of force by using the formula for the force acting on the opposite side of the rod F2 = (π* d^2 / 4)* P2 ==> (3.14*2^2/4)*2500 ==> 7853lb

Meaning a 2.5"dia cylinder will produce 12271lb!!

And then you used the 7850lbs * sin(7.5ー) = 1024lbs. Got it so far. I didn't get the argument that the cylinder is half way back, but there is so much waste anyway

The actual angle in the 2nd design is 10.79ー, resulting only 1470lbs at the closing end with 2500lb at the opening place (18.67ー). still not good.

I was struglling figuring out why the length of the rod is important as its not included in the calculations but I got it.

So it looks like I have to find a balance. Larger bore, means more force, but slower acting cylinder, while larger rod can achieve more applied force but also takes more time to full extend/retract.

What is an acceptable clamping force? (Don't tell me it depends what I want to use the grapple for!!! I know that!

Considering that a compact tractor cannot lift more than 1800lbs on the front pivot, does the target of 2000lbs sounds good enough?

Considering that a compact tractor cannot lift more than 1800lbs on the front pivot, does the target of 2000lbs sounds good enough?

These formulas are really interesting, I will stay up tonight to finish that!

These are the CAD files that I am making on Freecad 0.17 if you want to see them. You only need the "Master CAD" file if you do not want to edit. This is just temporary, the final will go to the GrabCAD

Quick question: These are the hydraulic specs of my tractor. Which number do I use for the calculations? The total flow (13.7) of the implement pump (8.2)??

Implement pump (gpm): 8.2

Steering pump (gpm): 5.5

Total flow (gpm): 13.7

Category, 3 pt hitch: CAT 1

Hitch Lift capacity (lb): 1,808

Lift control type: Manual

So, you end up with 7500lb of force by using the formula for the force acting on the opposite side of the rod F2 = (π* d^2 / 4)* P2 ==> (3.14*2^2/4)*2500 ==> 7853lb

Meaning a 2.5"dia cylinder will produce 12271lb!!

And then you used the 7850lbs * sin(7.5ー) = 1024lbs. Got it so far. I didn't get the argument that the cylinder is half way back, but there is so much waste anyway

The actual angle in the 2nd design is 10.79ー, resulting only 1470lbs at the closing end with 2500lb at the opening place (18.67ー). still not good.

I was struglling figuring out why the length of the rod is important as its not included in the calculations but I got it.

So it looks like I have to find a balance. Larger bore, means more force, but slower acting cylinder, while larger rod can achieve more applied force but also takes more time to full extend/retract.

What is an acceptable clamping force? (Don't tell me it depends what I want to use the grapple for!!! I know that!

These formulas are really interesting, I will stay up tonight to finish that!

These are the CAD files that I am making on Freecad 0.17 if you want to see them. You only need the "Master CAD" file if you do not want to edit. This is just temporary, the final will go to the GrabCAD

Quick question: These are the hydraulic specs of my tractor. Which number do I use for the calculations? The total flow (13.7) of the implement pump (8.2)??

Implement pump (gpm): 8.2

Steering pump (gpm): 5.5

Total flow (gpm): 13.7

Category, 3 pt hitch: CAT 1

Hitch Lift capacity (lb): 1,808

Lift control type: Manual

LD1

Epic Contributor

The comment about the rod half way down the lid....

The lid is a simple class 3 lever. ( Google that)

It has a fixed pivot, a point at which force is applied (where rod connects), and the teeth.

You are applying 1024# of force at a point roughly half way between the teeth and the pivot. That means the teeth are gonna have roughly half the force.

Get to around a 20 degree angle and I thin it will be fine

The lid is a simple class 3 lever. ( Google that)

It has a fixed pivot, a point at which force is applied (where rod connects), and the teeth.

You are applying 1024# of force at a point roughly half way between the teeth and the pivot. That means the teeth are gonna have roughly half the force.

Get to around a 20 degree angle and I thin it will be fine

texasranger556

Platinum Member

Use the implement pump numbers. The other pump is usually just for steering and transmission charge if it's hydro.

LD1

Epic Contributor

Why do you need pump flow for any calculations?

texasranger556

Platinum Member

Cycle time...