FredH

Platinum Member

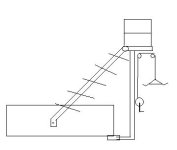

Several years ago , seen something similar to the picture below .

For the price they wanted , My Brother and Me decided to build our own .

Went to a local steel place that has a lot of recyled steel and purchased what We thought We needed . Some are rated at 300 pounds , while others are rated at 500 pounds . Based upon the size of their tube for 500 pounds , Ours is likely 1000 pounds or better . 2" x .25" wall round tube for main upright and vertical top . Vertical top is also supported by a brace of 4" x 1/2" flat bar , similar to the brace in the picture .

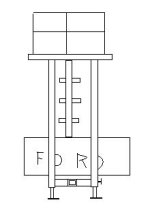

Started with a piece of 2" square tube that was a custom made hitch extension that was made for Me by a shop when I pulled my boat behind my camper . We added a piece of 1/2" plate to that at the end , to which We welded a 12" piece of 2.5" round tube that the 1st section of upright goes into . That 1st section , maybe 3' to 4' long , has a large piece of 1/2" plate welded to it for a electric winch . Then there is a coupler of 2.5" tube that the top section goes into .

The upright sections rotate 360 , thus once game is lifted it can be swung around to rear of vehicle for loading .

This past elk season , scored a 6 x 5 that hanging weight was almost 400 pounds without head and hide . Thus while hanging on the hoist while skinning , likely exceeded 500 pounds . Hoist No problem , H.F. winch , think it is the 2000 pound winch ??? , Well not so much . Got it almost all the way up , but had to manually lift / help it the last foot or so .

Yesterday , We decided to modify that hoist to make it easier to assemble . Lifting that top section up to drop it into the winch tube was a BI*** , with 3 of Us . Thus We ended up and cut the reciever extentsion , added a piece of 1 3/8" solid rod through out the entire length . Were We cut the extension tube , We welded a 7" x 1/2" round plate to the 1st section and also welded the solid rod to it . On the other piece of the extension , We welded another similar round plate , but did not weld the solid rod to that plate . 1 3/8" holes had been already drilled by My brother in the round plates , thus the rod is solid all the way through . In those round plates , the first has 2 holes , the second has 1 and the 2nd is also notched for 1/3 of the distance . Hard to explain , but the assembly , when installed in my hitch , will now rotate from vertical to a little past horizontal , thus eliminates having to " Lift " anything more than waist high . The 1st plate has those 2 holes , 1 hole for a pin to hold the hoist in a vertical position , the 2nd hole had a pin welded in place to act as a Stop , thus the reason for notching in the 2nd plate . When we lift it to vertical , it will not be able to go completly over the other side , as the second plate hits the stop .

I won't be able to get pictures till next week , but emailed my brother to go out to the shop to take a picture of Our " work " , so hopefully will add one later today .

Anyway , Now for a Question for You electrical and winch load smart ones . Truck is a 2006 dodge ram 2500 with a hemi , thus gas and single battery . I ran , I believe it is #4 gauge wire from the battery all the way to the rear of the truck , maybe say 15' for both wires . Connections at battery are large gauge , soldered connector's . Connection at back is one of these type :

From there it is also #4 guage to a small connector that I matched for the H.F. winch . Wire coming from winch is maybe 3' long , maybe 12 guage , maybe 10 ???

Winch never seem to " Overheat " just almost stopped near the top ( Like it was at capacity ?? ) . Truck was running the entire time , thus don't think that was a issue . Winch did not have entire cable out , looked like it was at 50% useable cable left . So Would I benefit from installing a second temp. battery in the bed to run the winch , with it being charged by the engine system . A bigger winch would likely be easiest ??? But will the current cable run it ???

We can build stuff , but winch loads , 12 volt electrical loads , etc.... puts me in Brain overload

Hopefully will add a picture shortly .

Fred H.

For the price they wanted , My Brother and Me decided to build our own .

Went to a local steel place that has a lot of recyled steel and purchased what We thought We needed . Some are rated at 300 pounds , while others are rated at 500 pounds . Based upon the size of their tube for 500 pounds , Ours is likely 1000 pounds or better . 2" x .25" wall round tube for main upright and vertical top . Vertical top is also supported by a brace of 4" x 1/2" flat bar , similar to the brace in the picture .

Started with a piece of 2" square tube that was a custom made hitch extension that was made for Me by a shop when I pulled my boat behind my camper . We added a piece of 1/2" plate to that at the end , to which We welded a 12" piece of 2.5" round tube that the 1st section of upright goes into . That 1st section , maybe 3' to 4' long , has a large piece of 1/2" plate welded to it for a electric winch . Then there is a coupler of 2.5" tube that the top section goes into .

The upright sections rotate 360 , thus once game is lifted it can be swung around to rear of vehicle for loading .

This past elk season , scored a 6 x 5 that hanging weight was almost 400 pounds without head and hide . Thus while hanging on the hoist while skinning , likely exceeded 500 pounds . Hoist No problem , H.F. winch , think it is the 2000 pound winch ??? , Well not so much . Got it almost all the way up , but had to manually lift / help it the last foot or so .

Yesterday , We decided to modify that hoist to make it easier to assemble . Lifting that top section up to drop it into the winch tube was a BI*** , with 3 of Us . Thus We ended up and cut the reciever extentsion , added a piece of 1 3/8" solid rod through out the entire length . Were We cut the extension tube , We welded a 7" x 1/2" round plate to the 1st section and also welded the solid rod to it . On the other piece of the extension , We welded another similar round plate , but did not weld the solid rod to that plate . 1 3/8" holes had been already drilled by My brother in the round plates , thus the rod is solid all the way through . In those round plates , the first has 2 holes , the second has 1 and the 2nd is also notched for 1/3 of the distance . Hard to explain , but the assembly , when installed in my hitch , will now rotate from vertical to a little past horizontal , thus eliminates having to " Lift " anything more than waist high . The 1st plate has those 2 holes , 1 hole for a pin to hold the hoist in a vertical position , the 2nd hole had a pin welded in place to act as a Stop , thus the reason for notching in the 2nd plate . When we lift it to vertical , it will not be able to go completly over the other side , as the second plate hits the stop .

I won't be able to get pictures till next week , but emailed my brother to go out to the shop to take a picture of Our " work " , so hopefully will add one later today .

Anyway , Now for a Question for You electrical and winch load smart ones . Truck is a 2006 dodge ram 2500 with a hemi , thus gas and single battery . I ran , I believe it is #4 gauge wire from the battery all the way to the rear of the truck , maybe say 15' for both wires . Connections at battery are large gauge , soldered connector's . Connection at back is one of these type :

From there it is also #4 guage to a small connector that I matched for the H.F. winch . Wire coming from winch is maybe 3' long , maybe 12 guage , maybe 10 ???

Winch never seem to " Overheat " just almost stopped near the top ( Like it was at capacity ?? ) . Truck was running the entire time , thus don't think that was a issue . Winch did not have entire cable out , looked like it was at 50% useable cable left . So Would I benefit from installing a second temp. battery in the bed to run the winch , with it being charged by the engine system . A bigger winch would likely be easiest ??? But will the current cable run it ???

We can build stuff , but winch loads , 12 volt electrical loads , etc.... puts me in Brain overload

Hopefully will add a picture shortly .

Fred H.