Warrenpfo

New member

- Joined

- Sep 12, 2025

- Messages

- 11

- Tractor

- Ford 6610

Good day all. Longtime reader first time poster so be kind.

To give some background i am somewhat practically minded and am good with my hands and dont have the funds to just buy new parts or get someone in to fix it so am hoping the combined brainpower and knowledge of the forum can help educate and solve my new to me Ford 7610 hydraulic niggles.

We bought this tractor about 3 years ago and the hydralics have never been great since day one. I can't profess to know the year so maybe starting there is a good place.

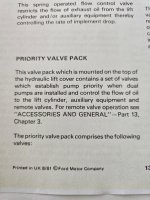

After that the tractor seems to only have the internal pump and no external just a blanking plate.

The rear lift arms are slow to respond but do work and there is a constant "bouncing" *cycling of the pump to retain lift of any rear impliment if left at full hight and I dont pull the diverter on the right side to stop flow to the arms once they are at the top.

The diverter would seem to divery flow to the loader which is painfully slow and only works if the diverter valve is out (will have to confirm if it's out or pushed in) and the rear lift arm lever is in the up position. If down it won't work.

Illupload what pictures I have in the hope it helps and the tractor sits at a small holding some 3h away and I am only there once a month so might be slow in responding with information when needed.

I dont use the rear valves although might like to keep there functionalllity for a tip trailer or log splitter one day but would really like to get to the bottom of the slow hydraulics and tidy it all up.

I have changed the filter under the right side step and the screen was cleaned, i assume this is the internal pump?

I have also changed the hydraulic fluid and checked to makes use the level is correct at the rear dipstick.

Something I have also noted is that if the tractor is nose up I loose hydralic power.

Hope this all makes sense and I appreciate and input but do treat me like a novice/dummy.

To give some background i am somewhat practically minded and am good with my hands and dont have the funds to just buy new parts or get someone in to fix it so am hoping the combined brainpower and knowledge of the forum can help educate and solve my new to me Ford 7610 hydraulic niggles.

We bought this tractor about 3 years ago and the hydralics have never been great since day one. I can't profess to know the year so maybe starting there is a good place.

After that the tractor seems to only have the internal pump and no external just a blanking plate.

The rear lift arms are slow to respond but do work and there is a constant "bouncing" *cycling of the pump to retain lift of any rear impliment if left at full hight and I dont pull the diverter on the right side to stop flow to the arms once they are at the top.

The diverter would seem to divery flow to the loader which is painfully slow and only works if the diverter valve is out (will have to confirm if it's out or pushed in) and the rear lift arm lever is in the up position. If down it won't work.

Illupload what pictures I have in the hope it helps and the tractor sits at a small holding some 3h away and I am only there once a month so might be slow in responding with information when needed.

I dont use the rear valves although might like to keep there functionalllity for a tip trailer or log splitter one day but would really like to get to the bottom of the slow hydraulics and tidy it all up.

I have changed the filter under the right side step and the screen was cleaned, i assume this is the internal pump?

I have also changed the hydraulic fluid and checked to makes use the level is correct at the rear dipstick.

Something I have also noted is that if the tractor is nose up I loose hydralic power.

Hope this all makes sense and I appreciate and input but do treat me like a novice/dummy.

Attachments

-

20240620_170211.jpg4.5 MB · Views: 34

20240620_170211.jpg4.5 MB · Views: 34 -

20240620_170206.jpg4.6 MB · Views: 30

20240620_170206.jpg4.6 MB · Views: 30 -

20221002_072851.jpg3.7 MB · Views: 31

20221002_072851.jpg3.7 MB · Views: 31 -

20220828_082300.jpg3 MB · Views: 26

20220828_082300.jpg3 MB · Views: 26 -

20220828_082306.jpg2.8 MB · Views: 27

20220828_082306.jpg2.8 MB · Views: 27 -

20220828_082328.jpg3.5 MB · Views: 28

20220828_082328.jpg3.5 MB · Views: 28 -

20221002_072841.jpg3.5 MB · Views: 28

20221002_072841.jpg3.5 MB · Views: 28 -

20220828_082232.jpg3.6 MB · Views: 28

20220828_082232.jpg3.6 MB · Views: 28 -

20220521_101719.jpg3.8 MB · Views: 28

20220521_101719.jpg3.8 MB · Views: 28 -

20220521_101638.jpg3.7 MB · Views: 33

20220521_101638.jpg3.7 MB · Views: 33

Last edited: