Spudland_Dave

Veteran Member

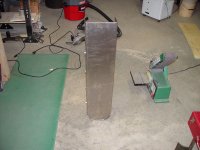

Last fall I posted pics of my Power Rake Build ALMOST done...I hadnt had time to build the Barrier and work on the Gauge wheels was in progress...tonight before hooking up the tiller I put the last touches on it...

Played around with it a little...works AWESOME. I can see why a PR is so desirable.

Played around with it a little...works AWESOME. I can see why a PR is so desirable.