downsizingnow48

Elite Member

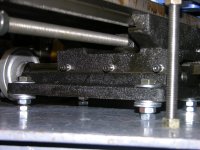

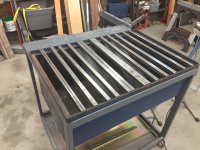

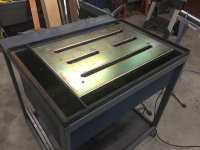

Last year I got an old side draft cutting table from a scrap yard. The first purpose was to set it up for plasma cutting with movable 1x1 and 1x2 slats (photo 1). It works well for material of many different shapes and for containing the grit. The second purpose was for welding. I transplanted the top from a HF folding table. It is a good working height and very steady (photo 2). Third purpose I just set up today, a stand for the Makita metal cutting saw. The saw sits on two pieces of 1/2" x 6" flat bar, and the side supports are 3-1/2" square tube. All the chips now go down in the table instead of thrown everywhere (photo 3). The fourth use will be as a drilling table. Next week's winter project will be a stand for the new mag drill (photo 4). I am also thinking of putting a piece of heavy plate on top to use as a heavier welding table and vise stand. Although I have never felt like I needed that, it is obviously very common to have, and there must be a good reason.

I especially like the way you utilized the square tube for work /length support on your saw base.

I especially like the way you utilized the square tube for work /length support on your saw base.