montejw

Gold Member

Is there enough room for a 90* drill attachment and shorty bit? If you get a left hand bit, use that. Or try a righty, drill a hole and tap in an "easy out".

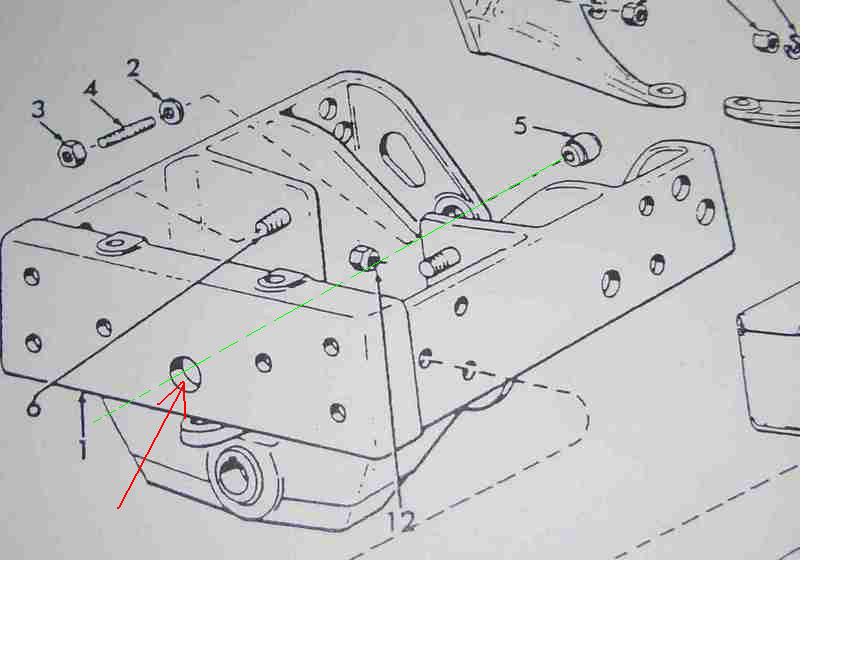

schmism said:so is this true? that this hole lines up with what would be the head of the nut/bolt

if so whats in the way of useing that hole to work through?

SPYDERLK said:Is the remanent just stuck in a NUT.

AlanB said:AlanB If it helps, I can lend you an aviation right angle drill and bits. You would not want to buy one I can assure you but I can post you one and you could send it back after the job.

workinallthetime said:i have a right angle air drill and they used to get be left handed drill bits from the local parts house all the time, im pretty sure you could work it into position and drill. i think the idea of soaking the bolf for a few days before the removal id very important, ive got a can or 2 of heat riser penitrate you can use also. let me know, you know where i am

CATMAN said:I, personally would try to find a way to hold a bit in the center of the hole if drilling is going to be an option. Predrill a round dowel(that fits in the hole) in the center. This OD of the dowel would just fit/slide into the area where the shank of the old bolt use to be. A wood dowel might be the easiest to find and probably serve the purpose for this function. The centering of your FIRST attempt to drill anything out, can be a real benefit IF you are unsuccessful and later(after you are forced to dissassemble more of the tractor) you find yourself trying to use bits, easyouts, taps, helicoils, etc. {I see this often on engine exhaust manifold studs into cylinder heads.} I believe harbor freight sells "transfer punches"(individually sized centering punch) but I think their max size is 1/2" diameter.

schmism said:so is this true? that this hole lines up with what would be the head of the nut/bolt

if so whats in the way of useing that hole to work through?

john_bud said:Hip Hip --> Hooray!

Or maybe it should be "plop plop fizz fizz, oh what a relief it is"!

Well the bolt has met it's match.

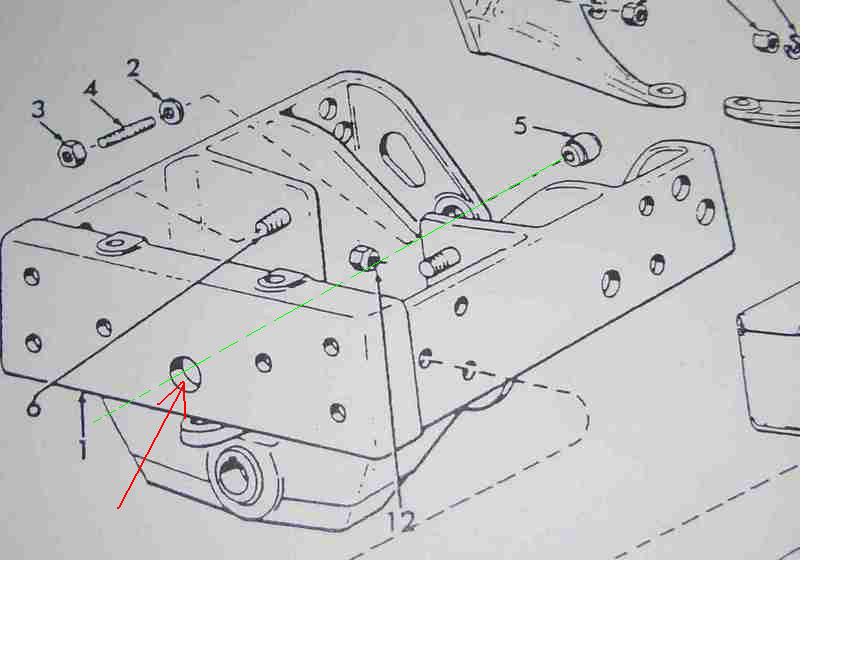

I couldn't wait and decided to just pop in the 1/8" hole. I put in the bushing and just lightly drilled.

Here's a picture of the bushings or drill guides.....

montejw said:That's cool! The drill bushings look like something to remember, pretty key to getting this bolt out.