Time to wrap up this thread. The thumb works great, exactly as planned. Everybody always shows their new thumb picking up some huge thing. See photo 1. The hydraulics are smooth, it is easy to pick up a can of beer without even denting it.

Before going further, I want to give a big tip of the hat to JJ and others on the hydraulics forum. JJ I have studied all your stuff for a year or more and couldn't have done this without the knowledge you have shared. Many thanks. Another hat tip to jfkrug who has been there and done that and I appreciate the comments received.

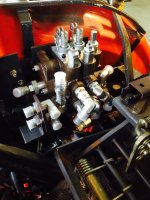

From the start I wanted an installation that was as unobtrusive as possible. The valve fits in the space between fender and seat, and all the hose connections fit under the valve or under the seat. Photo 2: main bracket up against the fender. Photo 3: valve installed. Facing forward, the front lever is ready to the left hand for controlling the

grapple. Facing backward, the rear lever is ready to the right hand for controlling the thumb.

The rear-facing disconnects are for the thumb or any other rear-mounted attachment, see Photo 4. The front-facing disconnects are for a

grapple, that is my next project. See Photos 5,6.

The hoses for the thumb follow the same path as the stick and bucket hoses. See Photos 7,8.

The new valve tank return port tees into the loader valve tank return, see Photo 9.

The hoses that go under the transmission and along the frame rails have steel wrap, see Photo 10. All other hoses have plastic wrap except the short hoses to the thumb cylinder that are steel wire wrap the same as Kubota uses for the bucket hoses.

I left the workport reliefs set at 1200psi. The thumb is strong enough to put one-inch dents in old yellow pine timbers. And delicate enough to pick up a beer can as above. I tested the reliefs by closing the bucket on the thumb, the thumb goes backward smoothly.