dfkrug

Super Member

- Joined

- Feb 3, 2004

- Messages

- 7,711

- Location

- Santa Cruz Mtns, CA

- Tractor

- 05 Kioti CK30HST w/ Prairie Dog backhoe, XN08 mini-X

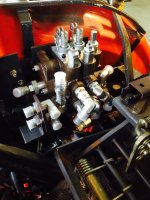

Photo 2,3. The progressive linkage works exactly as planned. When closed it tucks tightly against the stick, and

opens about 180 degrees.

In your 3rd photo above, it looks like the force exerted by the bkt on the thumb in the 180-deg position

will be quite high. I hope you do not over-pressure the thumb cyl.