ctgoldwing

Platinum Member

No claims for originality here. I have seen others do it but I decided to 'do it my way'. The thought was it would be a nice simple project to execute. Turned out there were little procurement bumps in the road that kept pushing back the finish date.

So the plan was to utilize a 200mm linear actuator (just about 8"). I measured the min and max distances between the pivot bolts and the were almost dead nuts 200mm.

First thing was to make a sketch of what I wanted to accomplish:

I used 1-1/4" OD aluminum tube with 1/4" wall thickness. At the bolt ends I drilled 20mm + holes to accommodate sleeves made from 20mm OD, 14mm ID. The original 12mm bolts were replaced with longer 60mm ones. They go through the sleeves. The sleeves are ~ 1-3/8" long (1/8" longer than the tube diameter). When the bolts are tightened the sleeves are fixed and the 1-1/4 tube can rotate freely as required as the release arms move.

The ends of the actuators were slightly larger than the ID of the 1-1/4 tube so I drilled that out as required. Believe me, I'm no machinist.

Here are the bits and pieces:

To control it I used a DPDT, center off, rocker switch. It provides the reversing of polarity of the 12 volts to the motor. I mounted it in the unused slot next to the range selector on my L3800. I just wanted it out of the way - no accidental 'oops'.

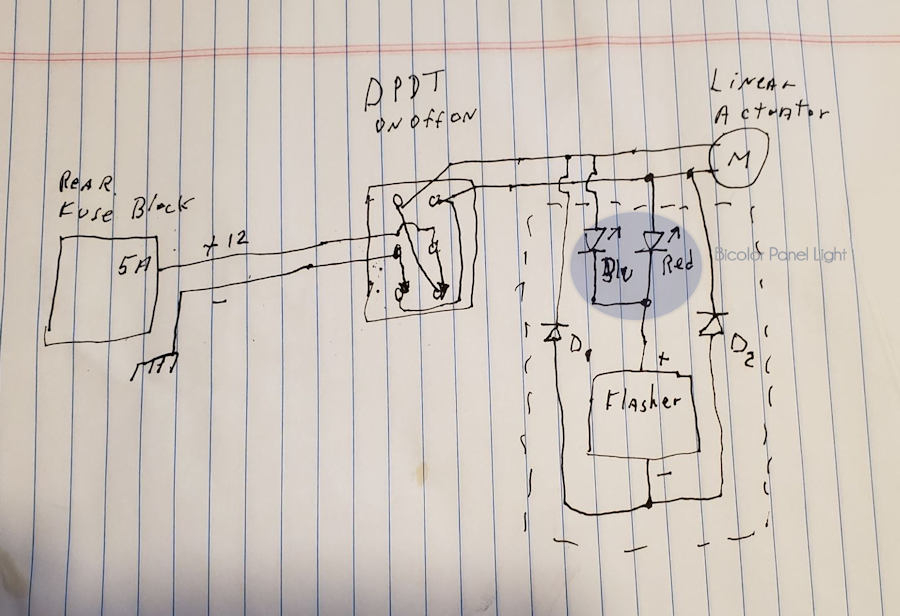

Additionally I mounted a very bright multicolor led on the dash to indicate when the actuator is energized (red for open, blue for closed). An ice cube sized electronic flasher was also added to make sure it was noticed. The wiring diagram is below. The led section is enclosed in dotted lines and is unnecessary for operation. All you need is the switch. There was change in the choice of led so a 30 ohm 10 watt dropping resistor is not shown - it is inserted between the led and the flasher. The panel light I was going to use was set up for 12 volt operation.

For previous projects I had installed a 6 position fuse block on the left rear fender. It's switched on with the key. That is where I obtained the 12 volts. My testing of the actuator indicated it draws about 1 amp. I used a 5 amp fuse.

The last thing I'm waiting for is some retractable cable to help keep the wiring neat and out of the 'danger zone' on the left fel arm. It does work. Time will tell for how long Here is my 1st mounting test pic. I ended up reversing it to get the wire close to left side.

Here is my 1st mounting test pic. I ended up reversing it to get the wire close to left side.

And a short Youtube of it finished: Demo of SSQA automation

It was a fun project and if need be the entire assembly can be removed in 3 minutes by unbolting 2 bolts, detach 2 spade fittings and then putting back the bolts with the sleeves (or find the original bolts).

So the plan was to utilize a 200mm linear actuator (just about 8"). I measured the min and max distances between the pivot bolts and the were almost dead nuts 200mm.

First thing was to make a sketch of what I wanted to accomplish:

I used 1-1/4" OD aluminum tube with 1/4" wall thickness. At the bolt ends I drilled 20mm + holes to accommodate sleeves made from 20mm OD, 14mm ID. The original 12mm bolts were replaced with longer 60mm ones. They go through the sleeves. The sleeves are ~ 1-3/8" long (1/8" longer than the tube diameter). When the bolts are tightened the sleeves are fixed and the 1-1/4 tube can rotate freely as required as the release arms move.

The ends of the actuators were slightly larger than the ID of the 1-1/4 tube so I drilled that out as required. Believe me, I'm no machinist.

Here are the bits and pieces:

To control it I used a DPDT, center off, rocker switch. It provides the reversing of polarity of the 12 volts to the motor. I mounted it in the unused slot next to the range selector on my L3800. I just wanted it out of the way - no accidental 'oops'.

Additionally I mounted a very bright multicolor led on the dash to indicate when the actuator is energized (red for open, blue for closed). An ice cube sized electronic flasher was also added to make sure it was noticed. The wiring diagram is below. The led section is enclosed in dotted lines and is unnecessary for operation. All you need is the switch. There was change in the choice of led so a 30 ohm 10 watt dropping resistor is not shown - it is inserted between the led and the flasher. The panel light I was going to use was set up for 12 volt operation.

For previous projects I had installed a 6 position fuse block on the left rear fender. It's switched on with the key. That is where I obtained the 12 volts. My testing of the actuator indicated it draws about 1 amp. I used a 5 amp fuse.

The last thing I'm waiting for is some retractable cable to help keep the wiring neat and out of the 'danger zone' on the left fel arm. It does work. Time will tell for how long

And a short Youtube of it finished: Demo of SSQA automation

It was a fun project and if need be the entire assembly can be removed in 3 minutes by unbolting 2 bolts, detach 2 spade fittings and then putting back the bolts with the sleeves (or find the original bolts).

Last edited: