Inside pics? Now you want inside pics?

I can probably round up a few.

The cabin was designed to have the feel of a USFS fire watch tower. I got the idea from a cabin built by an architect on some family land out of Lewistown, MT, which was featured in a cabin book I bought about ten years ago. The cabin is three floors: a 'basement' level which has a mechanical room and laundry, storage, and a bath with shower and sauna. The entry level off the front deck has a coatroom area, a powder room, and the master (and only) bedroom, the upstairs is all open with a kitchen area on one side and living area on the pond side. Plus the wraparound deck, which is a little over 500 sq. ft.

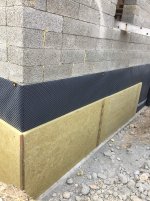

The idea was to have as many windows as possible on the upper floor, to really accentuate the 'lookout' feel, but we are on an elevated location prone to high winds and the roof (with 5' deep eaves to cover the deck) is like a giant sail, so I wanted to have the four corners of block walls solid, reinforced, and anchored right down to the footings so the top plate and roof trusses had something stout to grab onto. When you try to go with solid windows all the way around, there's just no shear strength to the wall and would have required essentially building a structural steel 'cage' between the roof and the block wall. I put one small interior wall in the kitchen area which provided a convenient chase for plumbing vent lines and electrical (and also provided a safety net of sorts for lines we might have forgotten to place in the exterior walls prior to pouring concrete). Here you can see the bare block and the scratch coat of stucco in preparation for the lime plaster.

We used closed-cell polyurethane foam for the roof insulation. Prior to spraying the foam a false roof deck was installed below the actual roof decking, so there is about 6" of open space under the actual roof deck to allow air circulation from the soffit vents to vent space around the curb for the skylight. An additional benefit of the foam was it really locks the roof trusses in and makes a VERY solid roof system. We also installed a whole house fan in the skylight vault to pull cool air into the cabin on summer mornings. With the thermal mass of the block walls, it's possible to maintain comfortable temperatures year-round without much in the way of heating and cooling costs. For the interior walls and ceilings, we used knotty pine T&G, although we did incorporate some of the metal siding from the outside in the stairwell, bath, etc. as an accent.

We went with a traditional finish on the knotty pine to enhance the cabin feel and the lime plaster has a very natural look, a matte (almost suede) texture, and mottling that gives it some depth, It was a royal PITA to do, but it was something I kind of had my heart set on from the beginning and it turned out great. The skylight is a 4x4' commercial Velux unit which admits a ton of diffuse light, even in the winter when the sun is very low on the horizon. And the little propane-fired fireplace can heat the area very quickly and also provides a nice atmosphere. And it even has a remote, so when I want a 'fire' all I have to do is click a button. I like a wood-burning stove as much as the next guy (and have one in the bunkhouse) but with 60 in the year view mirror, I also like not hauling wood up or ashes down the stairs.

Here's the sauna in the downstairs bath, which is accessed from the bedroom. Nice little kit from Finlandia which went together without any hassles.

And here's a snapshot I took a couple of weeks back as my wife and I were sitting on the deck watching a spring storm blow in. Even the clouds above seemed to be giving us a thumbs up on the cabin. Designing and building this cabin took a lot more time and a lot more money than I had originally intended (mainly because I kept upgrading things as we went, falling prey to the old "in for a penny, in for a pound" and "we're only going to do this once" mentality), but we're thrilled with the result and I hope we get to spend many years enjoying our little piece of Big Sky Country.