downsizingnow48

Elite Member

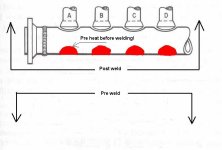

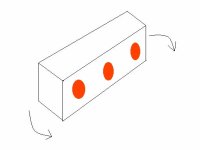

I am welding 5 brackets and gussets equally spaced along a 5 ft piece of square tubing (2x2x1/4).

One of the brackets will be right in the middle, two at each end, and then two equally spaced in between.

The brackets and gussets are 3/16 material. I took a photo below of how the finished assembly will go together.

There will be welds along three sides of the bracket, to the square tubing. And more welds along all of the places where the gusset meets with the square tubing and the bracket.

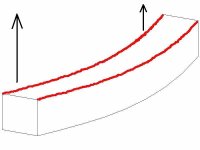

So this will be a lot of welding, in five locations, all on one side of the 5 ft piece of square tubing. The assembly has to end up straight, no warping.

I am thinking I might need to weld the 2x2x1/4 tube to something heavy to prevent warping. I have a long piece of 3x3x1/4 tube and another long piece of 4x4x3/16 tube.

But my question is, is this necessary. The 2x2x1/4 tube is pretty darn stiff. If I can get by without welding it to something else to prevent warp, that will make the job that much easier.

Any advice will be much appreciated, this is outside my range of experience.

One of the brackets will be right in the middle, two at each end, and then two equally spaced in between.

The brackets and gussets are 3/16 material. I took a photo below of how the finished assembly will go together.

There will be welds along three sides of the bracket, to the square tubing. And more welds along all of the places where the gusset meets with the square tubing and the bracket.

So this will be a lot of welding, in five locations, all on one side of the 5 ft piece of square tubing. The assembly has to end up straight, no warping.

I am thinking I might need to weld the 2x2x1/4 tube to something heavy to prevent warping. I have a long piece of 3x3x1/4 tube and another long piece of 4x4x3/16 tube.

But my question is, is this necessary. The 2x2x1/4 tube is pretty darn stiff. If I can get by without welding it to something else to prevent warp, that will make the job that much easier.

Any advice will be much appreciated, this is outside my range of experience.