dragoneggs

Super Star Member

- Joined

- Jun 9, 2013

- Messages

- 14,548

- Location

- Seabeck, Washington

- Tractor

- Kubota BX-25D, Kubota Z122RKW-42

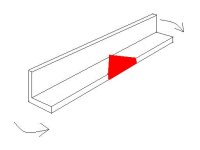

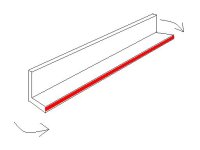

Okay another post to get some chatter going... what are folks thoughts on welding dissimilar thickness mild steel (and aluminum if different). Just wondering about any tricks or techniques that make for an optimum weld in these situations. For instance I am making a stand for my grinder. I have a piece of 12x12x1/2in plate for the bottom and some 2in square tube 1/8in wall for the post. I plan to butt the post against the center of the plate.

So, I have 1/8in edge weld to 1/2in field. Should I just weld as I would putting two 1/8in together, or do I increase volts, wire speed, change angle of MIG gun? Appreciate your thoughts and reasons.

So, I have 1/8in edge weld to 1/2in field. Should I just weld as I would putting two 1/8in together, or do I increase volts, wire speed, change angle of MIG gun? Appreciate your thoughts and reasons.