CalG

Super Member

- Joined

- Sep 29, 2011

- Messages

- 9,129

- Location

- vermont

- Tractor

- Hurlimann 435, Fordson E27n, Bolens HT-23, Kubota B7200, Kubota B2601

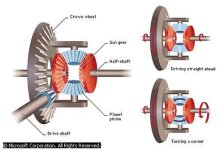

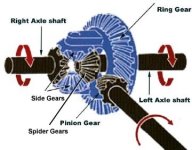

Me thinks with you're levers at equilibrium and a torque applied at the pinion that is equal or greater than the tractor center mass to centreline of rear axle the front will continue to rise. You got a few more lever's there in the dynamics of things that don't diss appear in some gear case housing!:thumbsup:

I need help visualizing which levers are missing.

For the sake of illustration.

Consider a simple wheel tractor that is powered by hydraulic motors at each axle. There are many real world examples so constructed. More so in heavy equipment than in compact tractors.

Egon, will you describe the levers you see are important in such a system