TSO

Elite Member

Been wanting a grapple for awhile, but ended up spending the money on other things  ... oh well. So, recently, I found this new 60" Rock bucket on a local auction site, and won it for $228. :thumbsup: I figured I'd either sell it for a profit OR make a grapple out of it. Well, I wen't with option 2, so here's the project so far:

... oh well. So, recently, I found this new 60" Rock bucket on a local auction site, and won it for $228. :thumbsup: I figured I'd either sell it for a profit OR make a grapple out of it. Well, I wen't with option 2, so here's the project so far:

The bucket:

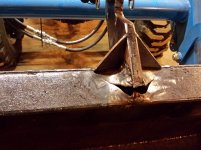

The metal: I picked up all the metal needed for less than $100 from my local metal shop (using scraps & cut-off's like always ) The lid/tines are 3/8" thickness steel X 5" width. I cut them to shape and welded them into the proper angle. Added some biting-teeth to them as well.

) The lid/tines are 3/8" thickness steel X 5" width. I cut them to shape and welded them into the proper angle. Added some biting-teeth to them as well.

The lid is attached to the bucket with two 3/4" bolts at the pivots. The top of that bucket is 3" tube steel, so it's a good strong base to mount things, although I used some 3"x3" angle iron as the pivot mounts. The lid opens to around 36".

This is the progress so far, but it's only been a couple days so it's moving pretty quickly I suppose. Next step is to fab up the cylinder mounts, and add some more bracing & a center half-tooth to the lid.

-----------------------------

QUESTION for the guys that have already used their hydraulic remotes, as I haven't looked at mine yet: What size & style connectors did you use to connect to the factory remotes? How much hose is needed to run up to the front from the rear remotes?

The bucket:

The metal: I picked up all the metal needed for less than $100 from my local metal shop (using scraps & cut-off's like always

The lid is attached to the bucket with two 3/4" bolts at the pivots. The top of that bucket is 3" tube steel, so it's a good strong base to mount things, although I used some 3"x3" angle iron as the pivot mounts. The lid opens to around 36".

This is the progress so far, but it's only been a couple days so it's moving pretty quickly I suppose. Next step is to fab up the cylinder mounts, and add some more bracing & a center half-tooth to the lid.

-----------------------------

QUESTION for the guys that have already used their hydraulic remotes, as I haven't looked at mine yet: What size & style connectors did you use to connect to the factory remotes? How much hose is needed to run up to the front from the rear remotes?