Well, OK... I finished the grapple build.

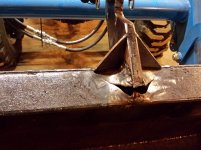

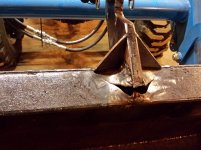

Here's the "hydraulic brackets" I built & shaped for maximum clearance for the geometry of the cylinder.

Here's the "lid" finished and painted.

Also made a trip today to my local Farm supply store and picked up all the necessary hoses & fittings for the hydraulics. In case anyone is following along with this, I needed approx 17 feet of hose to reach from the rear remotes to the front loader cross support. They sold lengths of 10' and 7' and together, those worked perfectly. I then used a 4' and 5' hose to connect to the ends (1 is longer so it can reach the farther cylinder attach point) of the longer hose section on the loader cross support. I added quick-connect fittings so it can easily come on/off. I was going to go with 1/4" but they didn't have that in long lengths, so I stuck with 3/8" and that works fine. The grapple lid opens/closes at a nice rate.

After I finished everything I tried it out, and quickly broke the large cylinder bracket off of the bucket top. I then welded on some support tabs, better connecting the brackets to the bucket. This proved to work very well, however, since I neglected to first weld on a thicker piece of angle-iron to the top of the bucket, I tore the metal right off the bucket when using it tonight.

Bad news is I'm going to have to try to retro-fit some kind of support that will keep the bucket from tearing again...

Good news is that the grapple works very well. Before that tore, I was able to grab & move logs, brush, and even a large 24" + diameter X 8 foot long Log... that was heavy enough to lift the back tires, even WITH my HD 8' back blade !!! The grapple was able to clamp on it and keep it held, so the design works! Just need to reinforce that top.